Cov khoom

Polybutylene Terephthalate (PBT)

Polybutylene Terephthalate (PBT)

Kev Taw Qhia Txog Khoom

Poly butylene Terephthalate yog cov xim dawb lossis daj daj translucent rau opaque thermoplastic polyester particles. Poly butylene Terephthalate (PBT) muaj cov khoom siv zoo heev, cov khoom siv hluav taws xob rwb thaiv tsev, roj tsis kam, tshuaj tiv thaiv corrosion, yooj yim molding thiab tsis nqus dej noo, thiab lwm yam, thiab yog cov khoom siv feem ntau siv rau optical fiber secondary coating.

Hauv cov xov fiber ntau optical, cov fiber ntau optical tsis yooj yim puas. Txawm hais tias lub zog kho tshuab ntawm cov fiber ntau optical tau zoo dua tom qab txheej thawj zaug, qhov yuav tsum tau ua rau cabling tseem tsis txaus, yog li ntawd yuav tsum muaj txheej thib ob. Txheej thib ob yog txoj kev tiv thaiv tshuab tseem ceeb tshaj plaws rau cov fiber ntau optical hauv cov txheej txheem tsim cov xov fiber ntau optical, vim tias txheej thib ob tsis tsuas yog muab kev tiv thaiv tshuab ntxiv rau kev sib txhuam thiab kev ntxhov siab, tab sis kuj tsim cov fiber ntau optical ntev dhau. Vim nws cov khoom siv lub cev thiab tshuaj zoo, Poly butylene terephthalate feem ntau yog siv los ua cov khoom siv extrusion rau txheej thib ob ntawm cov fiber ntau optical hauv cov xov fiber ntau optical sab nraum zoov.

Peb tuaj yeem muab OW-6013, OW-6015 thiab lwm yam khoom siv Poly butylene Terephthalate rau txheej txheej thib ob ntawm cov xov hlau fiber ntau.

cov yam ntxwv

Cov khoom PBT uas peb muab muaj cov yam ntxwv hauv qab no:

1) Kev ruaj khov zoo. Me me shrinkage nplai, me me ntim hloov pauv hauv kev siv, zoo stability hauv kev tsim.

2) Lub zog kho tshuab siab. Modulus loj, kev ua tau zoo ntawm kev nthuav dav, lub zog tensile siab. Tus nqi siab tiv thaiv sab nraud ntawm lub raj yog siab dua li tus qauv.

3) Kub siab heev. Kev ua tau zoo heev nyob rau hauv cov khoom loj thiab cov khoom me.

4) Kev tiv thaiv hydrolysis. Nrog kev tiv thaiv zoo heev rau hydrolysis, ua rau cov xov hluav taws xob fiber ntau lub neej ntev dua li cov qauv xav tau.

5) Tshuaj lom neeg tsis kam. Tshuaj lom neeg tsis kam zoo thiab sib xws zoo nrog cov tshuaj fiber thiab cov tshuaj cable, tsis yooj yim rau corroded.

Daim Ntawv Thov

Feem ntau yog siv rau kev tsim cov txheej txheem thib ob ntawm cov fiber ntau ntawm cov xov hlau fiber ntau sab nraum zoov.

Cov Kev Ntsuas Kev Txawj

OW-PBT 6013

| Tsis yog. | Khoom kuaj | Chav tsev | Qhov Yuav Tsum Tau Ua | Tus nqi |

| 1 | Qhov Ceev | g/cm23 | 1.25 ~ 1.35 | 1.31 |

| 2 | Tus nqi ntws yaj (250 ℃, 2160g) | g/10 feeb | 7.0 ~ 15.0 | 12.5 |

| 3 | Cov dej noo | % | ≤0.05 | 0.03 |

| 4 | Kev nqus dej | % | ≤0.5 | 0.3 |

| 5 | Lub zog tensile ntawm cov zis | MPa | ≥50 | 52.5 |

| Kev ntev ntawm cov qoob loo | % | 4.0 ~ 10.0 | 4.4 | |

| Rhuav tshem kev ncab | % | ≥100 | 326.5 | |

| Modulus ntawm elasticity | MPa | ≥2100 | 2241 | |

| 6 | Flexural Modulus | MPa | ≥2200 | 2243 |

| Lub zog flexural | MPa | ≥60 | 76.1 | |

| 7 | Qhov kub yaj | ℃ | 210 ~ 240 | 216 |

| 8 | Qhov nyuaj ntawm ntug dej hiav txwv (HD) | / | ≥70 | 73 |

| 9 | Izod cuam tshuam (23 ℃) | kJ/㎡ | ≥5.0 | 9.7 |

| Izod cuam tshuam (-40 ℃) | kJ/㎡ | ≥4.0 | 7.7 | |

| 10 | Coefficient ntawm Linear Expansion (23 ℃ ~ 80 ℃) | 10-4K-1 | ≤1.5 | 1.4 |

| 11 | Ntim resistivity | Ω·cm | ≥1.0 × 1014 | 3.1 × 1016 |

| 12 | Kub hloov pauv kub (1.80MPa) | ℃ | ≥55 | 58 |

| Kub hloov pauv kub (0.45MPa) | ℃ | ≥170 | 178 | |

| 13 | Kev ua kom sov ntawm cov dej | |||

| Lub Zog Tensile ntawm Yield | MPa | ≥50 | 51 | |

| Kev ntev thaum tawg | % | ≥10 | 100 | |

| 14 | Kev sib raug zoo ntawm cov khoom siv thiab cov khoom sib xyaw ua ke | |||

| Lub Zog Tensile ntawm Yield | MPa | ≥50 | 51.8 | |

| Kev ntev thaum tawg | % | ≥100 | 139.4 | |

| 15 | Lub raj xa dej tawm tsam sab siab | N | ≥800 | 825 |

| Lus Cim: Hom Poly butylene Terephthalate (PBT) no yog cov khoom siv txheej txheem thib ob rau cable optical. | ||||

OW-PBT 6015

| Tsis yog. | Khoom kuaj | Chav tsev | Qhov Yuav Tsum Tau Ua | Tus nqi |

| 1 | Qhov Ceev | g/cm23 | 1.25 ~ 1.35 | 1.31 |

| 2 | Tus nqi ntws yaj (250 ℃, 2160g) | g/10 feeb | 7.0 ~ 15.0 | 12.6 |

| 3 | Cov dej noo | % | ≤0.05 | 0.03 |

| 4 | Kev nqus dej | % | ≤0.5 | 0.3 |

| 5 | Lub zog tensile ntawm cov zis | MPa | ≥50 | 55.1 |

| Kev ntev ntawm cov qoob loo | % | 4.0 ~ 10.0 | 5.2 | |

| Kev ntev thaum tawg | % | ≥100 | 163 | |

| Modulus ntawm elasticity | MPa | ≥2100 | 2316 | |

| 6 | Flexural Modulus | MPa | ≥2200 | 2311 |

| Lub zog flexural | MPa | ≥60 | 76.7 | |

| 7 | Qhov kub yaj | ℃ | 210 ~ 240 | 218 |

| 8 | Qhov nyuaj ntawm ntug dej hiav txwv (HD) | / | ≥70 | 75 |

| 9 | Izod cuam tshuam (23 ℃) | kJ/㎡ | ≥5.0 | 9.4 |

| Izod cuam tshuam (-40 ℃) | kJ/㎡ | ≥4.0 | 7.6 | |

| 10 | Coefficient ntawm Linear Expansion (23 ℃ ~ 80 ℃) | 10-4K-1 | ≤1.5 | 1.44 |

| 11 | Ntim resistivity | Ω·cm | ≥1.0 × 1014 | 4.3 × 1016 |

| 12 | Kub hloov pauv kub (1.80MPa) | ℃ | ≥55 | 58 |

| Kub hloov pauv kub (0.45MPa) | ℃ | ≥170 | 174 | |

| 13 | Kev ua kom sov ntawm cov dej | |||

| Lub Zog Tensile ntawm Yield | MPa | ≥50 | 54.8 | |

| Kev ntev thaum tawg | % | ≥10 | 48 | |

| 14 | Kev sib raug zoo ntawm cov khoom siv thiab cov khoom sib xyaw ua ke | |||

| Lub Zog Tensile ntawm Yield | MPa | ≥50 | 54.7 | |

| Kev ntev thaum tawg | % | ≥100 | 148 | |

| 15 | Lub raj xa dej tawm tsam sab siab | N | ≥800 | 983 |

| Lus Cim: Cov Poly butylene Terephthalate (PBT) no muaj kev tiv taus siab, thiab tsim nyog rau kev tsim cov txheej txheej thib ob ntawm cov xov hlau micro-optical cua. | ||||

Ntim Khoom

Cov khoom siv PBT yog ntim rau hauv 1000kg lossis 900kg polypropylene woven hnab sab nraud ntim, kab nrog lub hnab ntawv txhuas; lossis 25kg kraft ntawv hnab sab nraud ntim, kab nrog lub hnab ntawv txhuas.

Tom qab ntim khoom tiav lawm, muab tso rau ntawm lub pallet.

1) 900kg tuj hnab loj: 1.1m * 1.1m * 2.2m

2) 1000kg tuj hnab loj: 1.1m * 1.1m * 2.3m

Kev Khaws Cia

1) Cov khoom yuav tsum khaws cia rau hauv qhov chaw huv si, huv si, qhuav thiab muaj cua nkag.

2) Cov khoom yuav tsum khaws cia kom deb ntawm cov tshuaj lom neeg thiab cov tshuaj corrosive, yuav tsum tsis txhob muab sib dhos ua ke nrog cov khoom uas yooj yim hlawv thiab yuav tsum tsis txhob nyob ze rau cov chaw hluav taws.

3) Cov khoom yuav tsum tsis txhob raug tshav ntuj ncaj qha thiab los nag.

4) Cov khoom yuav tsum tau ntim kom tag nrho kom tsis txhob muaj dej noo thiab ua rau muaj kuab paug.

5) Lub sijhawm khaws cia ntawm cov khoom ntawm qhov kub thiab txias yog 12 lub hlis txij li hnub tsim khoom.

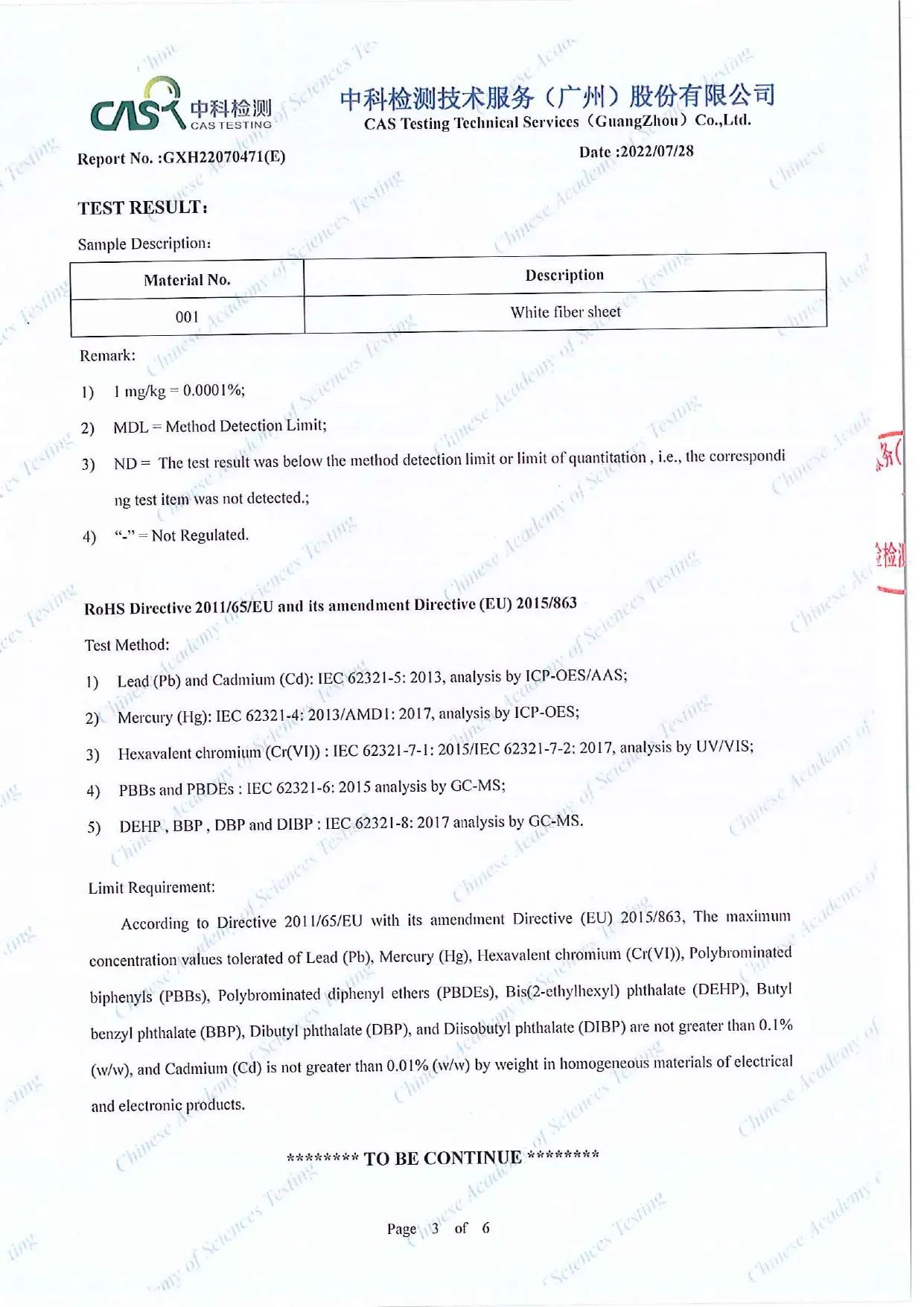

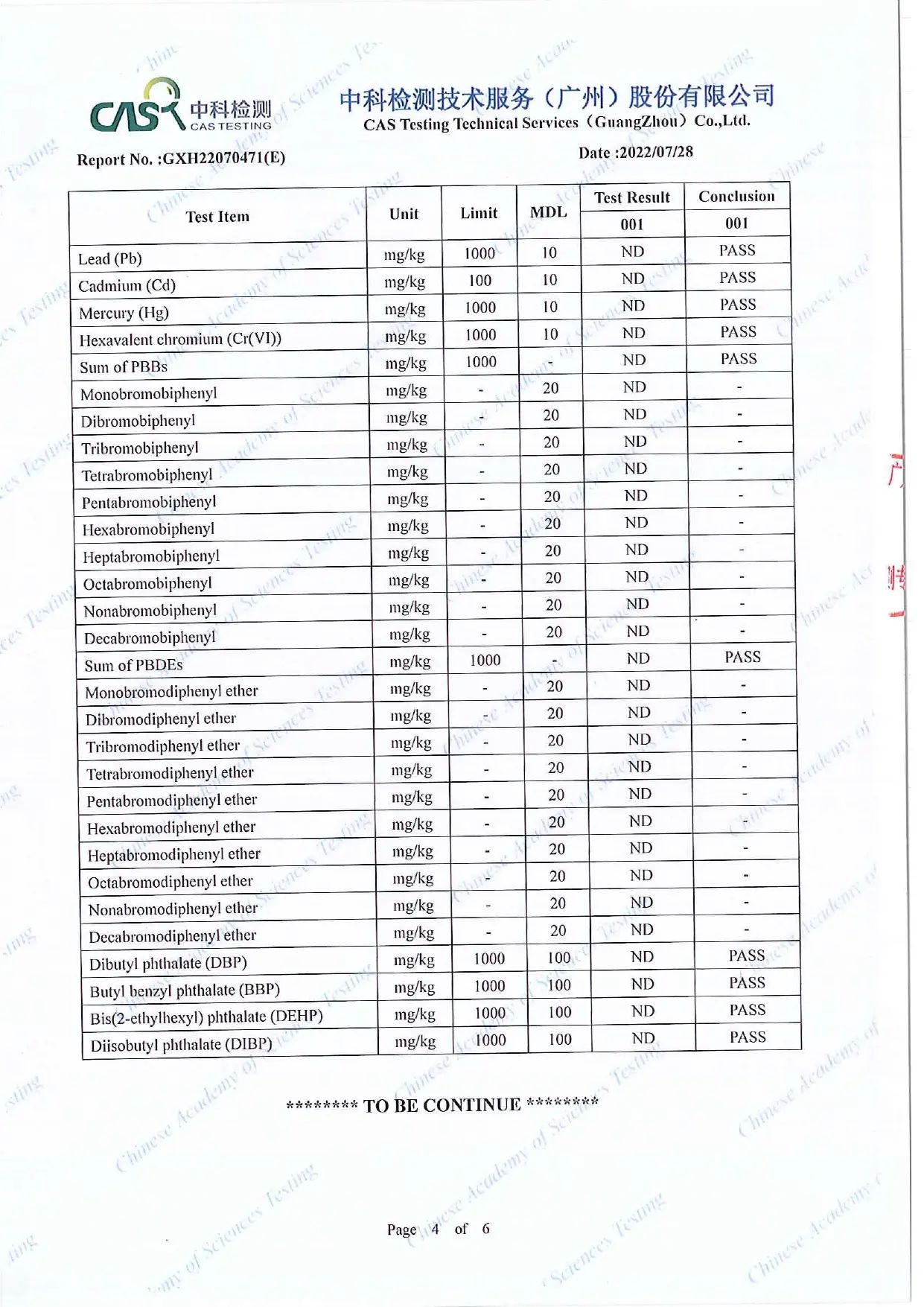

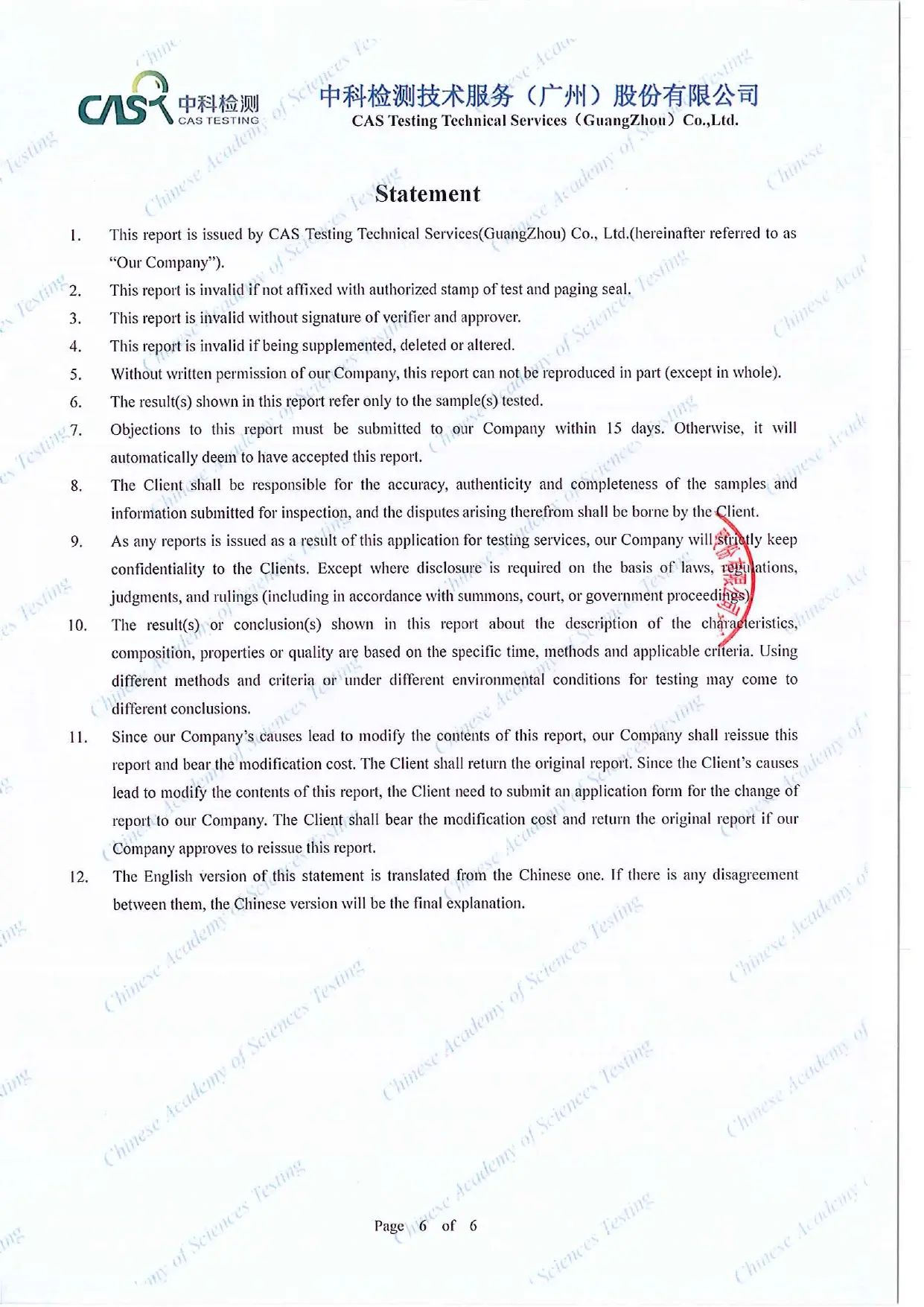

Daim Ntawv Pov Thawj

Cov Lus Teb Rov Qab

COV LUS QHIA DAWB

IB LUB NTIJ TEB CHAWS cog lus tias yuav muab cov neeg siv khoom nrog cov khoom siv hlau thiab cable zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws.

Koj tuaj yeem thov kom tau ib qho qauv dawb ntawm cov khoom uas koj xav tau uas txhais tau tias koj txaus siab siv peb cov khoom rau kev tsim khoom

Peb tsuas yog siv cov ntaub ntawv sim uas koj txaus siab tawm tswv yim thiab qhia ua qhov kev txheeb xyuas cov yam ntxwv thiab qhov zoo ntawm cov khoom, thiab tom qab ntawd pab peb tsim kom muaj lub kaw lus tswj xyuas zoo dua kom txhim kho kev ntseeg siab thiab lub hom phiaj yuav khoom ntawm cov neeg siv khoom, yog li thov rov qab lees paub dua.

Koj Sau Tau Daim Ntawv Ntawm Sab Xis Kom Tau Ib Qho Qauv Dawb

Cov Lus Qhia Txog Daim Ntawv Thov

1. Tus Neeg Siv Khoom Muaj Ib Tus Account Thoob Ntiaj Teb Express Delivery Account Lossis Them Tus Nqi Thauj Khoom (Tus Nqi Thauj Khoom Rov Qab Tau Hauv Daim Ntawv Txiav Txim)

2. Tib lub tsev kawm ntawv tsuas tuaj yeem thov tau ib qho qauv dawb ntawm tib yam khoom, thiab tib lub tsev kawm ntawv tuaj yeem thov tau txog li tsib qho qauv ntawm cov khoom sib txawv dawb hauv ib xyoos.

3. Cov Qauv Tsuas Yog Rau Cov Neeg Siv Khoom Hlau Thiab Cable Hoobkas, Thiab Tsuas Yog Rau Cov Neeg Ua Haujlwm Hauv Chaw Kuaj Xyuas Rau Kev Ntsuas Ntau Lawm Lossis Kev Tshawb Fawb

COV NTAUB NTAWV QHIA

DAIM NTAWV THOV QHIA DAWB

Thov Sau Cov Qauv Qhia Txog Qhov Yuav Tsum Tau Ua, Lossis Piav Qhia Luv Luv Txog Cov Kev Xav Tau Ua Haujlwm, Peb Yuav Pom Zoo Cov Qauv Rau Koj

Tom qab xa daim foos, cov ntaub ntawv koj sau rau hauv yuav raug xa mus rau ONE WORLD keeb kwm yav dhau los kom ua tiav ntxiv los txiav txim siab cov khoom lag luam thiab cov ntaub ntawv chaw nyob nrog koj. Thiab kuj tseem yuav tiv tauj koj los ntawm xov tooj. Thov nyeem peb cov ntaub ntawvTxoj Cai Tswjfwm Ntiag TugYog xav paub ntxiv.