Qhov kev ua tau zoo ntawm cov ntaub ntawv rwb thaiv tsev cuam tshuam ncaj qha rau qhov zoo, kev ua haujlwm zoo thiab qhov dav ntawm kev siv cov xov hlau thiab cov cables. Qhov kev ua tau zoo ntawm cov ntaub ntawv rwb thaiv tsev cuam tshuam ncaj qha rau qhov zoo, kev ua haujlwm zoo thiab qhov dav ntawm kev siv cov xov hlau thiab cov cables.

1. Cov xov hlau thiab cov cables PVC polyvinyl chloride

Polyvinyl chloride (tom qab no hu uaPVC) Cov ntaub ntawv rwb thaiv tsev yog cov khoom sib xyaw uas cov stabilizers, plasticizers, flame retardants, roj nplua nyeem thiab lwm yam khoom ntxiv rau hauv PVC hmoov. Raws li cov ntawv thov sib txawv thiab cov yam ntxwv xav tau ntawm cov xov hlau thiab cables, cov mis raug kho raws li. Tom qab ntau xyoo ntawm kev tsim khoom thiab daim ntawv thov, kev tsim khoom thiab kev ua cov thev naus laus zis ntawm PVC tam sim no tau dhau los ua neeg laus heev. Cov ntaub ntawv rwb thaiv tsev PVC muaj cov ntawv thov dav heev hauv thaj chaw ntawm cov xov hlau thiab cables thiab muaj cov yam ntxwv sib txawv ntawm nws tus kheej:

A. Cov thev naus laus zis tsim khoom yog laus lawm, yooj yim rau kev tsim thiab ua. Piv nrog rau lwm hom ntaub ntawv rwb thaiv tsev cable, nws tsis tsuas yog muaj tus nqi qis xwb, tab sis kuj tseem tuaj yeem tswj tau qhov sib txawv ntawm xim, ci ntsa iab, luam ntawv, ua haujlwm tau zoo, mos thiab tawv ntawm qhov chaw hlau, qhov nplaum ntawm tus neeg coj, nrog rau cov khoom siv kho tshuab thiab lub cev thiab cov khoom siv hluav taws xob ntawm cov hlau nws tus kheej.

B. Nws muaj kev ua tau zoo heev ntawm cov nplaim taws, yog li cov xov hlau PVC insulated tuaj yeem ua tau raws li cov qib nplaim taws uas tau teev tseg los ntawm ntau yam qauv.

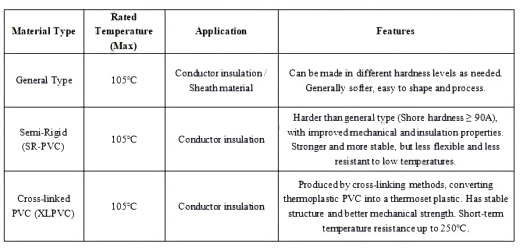

C. Hais txog kev tiv taus kub, los ntawm kev ua kom zoo dua thiab kev txhim kho cov qauv khoom siv, cov hom PVC rwb thaiv tsev uas siv tam sim no feem ntau suav nrog peb pawg hauv qab no:

Hais txog qhov ntsuas hluav taws xob, nws feem ntau siv rau hauv cov qib hluav taws xob ntsuas ntawm 1000V AC thiab qis dua, thiab tuaj yeem siv dav hauv kev lag luam xws li cov khoom siv hauv tsev, cov twj paj nruag thiab cov meters, teeb pom kev zoo, thiab kev sib txuas lus hauv network.

PVC kuj muaj qee qhov tsis zoo uas txwv nws daim ntawv thov:

A. Vim nws muaj cov tshuaj chlorine ntau, nws yuav tso tawm ntau cov pa luam yeeb tuab thaum hlawv, uas tuaj yeem ua rau tsis muaj zog, cuam tshuam rau qhov pom kev, thiab tsim qee cov carcinogens thiab HCl roj, ua rau muaj kev puas tsuaj loj rau ib puag ncig. Nrog rau kev txhim kho ntawm cov pa luam yeeb tsawg xoom halogen rwb thaiv tsev cov khoom siv thev naus laus zis, maj mam hloov PVC rwb thaiv tsev tau dhau los ua qhov tsis zam hauv kev txhim kho cov cables.

B. Cov rwb thaiv tsev PVC ib txwm muaj kev tiv thaiv tsis zoo rau cov kua qaub thiab alkalis, roj cua sov, thiab cov kuab tshuaj organic. Raws li lub hauv paus ntsiab lus tshuaj lom neeg ntawm cov yaj zoo li, cov xov hlau PVC yooj yim rau kev puas tsuaj thiab tawg hauv qhov chaw tshwj xeeb uas tau hais. Txawm li cas los xij, nrog nws cov kev ua tau zoo heev thiab tus nqi qis. Cov xov hlau PVC tseem siv dav hauv cov khoom siv hauv tsev, cov khoom siv teeb pom kev zoo, cov khoom siv kho tshuab, cov twj paj nruag thiab cov ntsuas, kev sib txuas lus hauv network, kev tsim kho xov hlau thiab lwm yam teb.

2. Cov xov hlau polyethylene thiab cov cables uas sib txuas ua ke

PE txuas nrog (txuas ntxiv mus hu uaXLPE) yog ib hom polyethylene uas tuaj yeem hloov pauv los ntawm cov qauv molecular linear mus rau cov qauv peb-seem peb-seem nyob rau hauv qee qhov xwm txheej nyob rau hauv kev ua ntawm cov hluav taws xob siab lossis cov neeg sawv cev sib txuas. Tib lub sijhawm, nws hloov pauv los ntawm thermoplastic mus rau insoluble thermosetting yas.

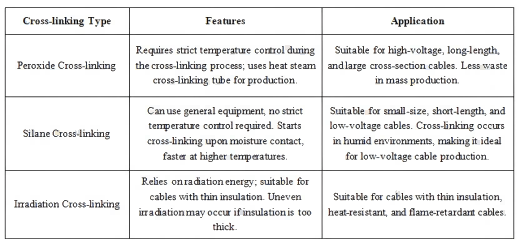

Tam sim no, nyob rau hauv daim ntawv thov ntawm hlau thiab cable rwb thaiv tsev, muaj peb txoj kev sib txuas:

A. Kev sib txuas ntawm cov tshuaj peroxide: Nws yog thawj zaug siv cov tshuaj polyethylene ua ke nrog cov neeg sawv cev sib txuas thiab cov tshuaj antioxidants, thiab tom qab ntawd ntxiv lwm yam khoom raws li qhov xav tau los tsim cov khoom sib xyaw polyethylene uas sib txuas tau. Thaum lub sijhawm extrusion, kev sib txuas tshwm sim los ntawm cov kav dej sib txuas nrog cov pa kub.

B. Silane cross-linking (dej sov cross-linking): Qhov no kuj yog ib txoj kev sib txuas tshuaj lom neeg. Nws lub tshuab tseem ceeb yog sib txuas organosiloxane thiab polyethylene nyob rau hauv cov xwm txheej tshwj xeeb, ib

thiab qib kev sib txuas ntawm feem ntau tuaj yeem ncav cuag li 60%.

C. Kev sib txuas ntawm cov hluav taws xob: Nws siv cov hluav taws xob muaj zog xws li R-rays, alpha rays, thiab electron rays los ua kom cov pa roj carbon hauv polyethylene macromolecules ua haujlwm thiab ua rau muaj kev sib txuas. Cov hluav taws xob muaj zog feem ntau siv hauv cov xov hlau thiab cov cables yog cov hluav taws xob tsim los ntawm cov electron accelerators. Vim tias qhov kev sib txuas no vam khom lub zog ntawm lub cev, nws yog ib feem ntawm kev sib txuas ntawm lub cev.

Cov txheej txheem sib txuas peb yam saum toj no muaj cov yam ntxwv thiab daim ntawv thov sib txawv:

Piv nrog rau thermoplastic polyethylene (PVC), XLPE rwb thaiv tsev muaj cov txiaj ntsig zoo li nram no:

A. Nws tau txhim kho qhov kev tiv thaiv kev hloov pauv kub, txhim kho cov khoom siv kho tshuab ntawm qhov kub siab, thiab txhim kho qhov kev tiv thaiv kev tawg ntawm ib puag ncig thiab kev laus ntawm cua sov.

B. Nws muaj kev ruaj khov tshuaj lom neeg zoo dua thiab tiv taus cov kuab tshuaj, txo cov dej txias, thiab feem ntau tswj tau qhov ua tau zoo hluav taws xob qub. Qhov kub ua haujlwm ntev tuaj yeem ncav cuag 125 ℃ thiab 150 ℃. Cov hlau thiab cable uas muaj polyethylene cross-linked insulated kuj txhim kho qhov tsis kam luv luv, thiab nws qhov tsis kam kub luv luv tuaj yeem ncav cuag 250 ℃, rau cov hlau thiab cable uas muaj tib lub tuab, lub peev xwm nqa tam sim no ntawm polyethylene cross-linked yog ntau dua.

C. Nws muaj cov khoom siv kho tshuab zoo heev, tiv taus dej thiab tiv taus hluav taws xob, yog li nws siv dav hauv ntau qhov chaw. Xws li: cov xov hlau txuas sab hauv rau cov khoom siv hluav taws xob, cov xov hlau tsav tsheb, cov xov hlau teeb pom kev zoo, cov xov hlau tswj lub teeb liab qis rau lub tsheb, cov xov hlau locomotive, cov xov hlau thiab cov xov hlau rau hauv av, cov xov hlau tiv thaiv ib puag ncig rau cov mines, cov xov hlau Marine, cov xov hlau rau kev teeb tsa hluav taws xob nuclear, cov xov hlau siab rau TV, cov xov hlau siab rau X-RAY tua hluav taws, thiab cov xov hlau thiab cov xov hlau xa hluav taws xob, thiab lwm yam.

Cov xov hlau thiab cov cables XLPE insulated muaj cov txiaj ntsig zoo tab sis lawv kuj muaj qee qhov tsis zoo uas txwv lawv daim ntawv thov:

A. Kev ua haujlwm tsis zoo uas tiv taus cua sov. Thaum ua thiab siv cov xov hlau tshaj qhov kub uas lawv ntsuas, nws yooj yim rau cov xov hlau lo rau ib leeg. Hauv cov xwm txheej hnyav, nws tuaj yeem ua rau puas tsuaj rau cov khoom rwb thaiv tsev thiab luv luv.

B. Tsis kam ua kom sov zoo. Thaum kub tshaj 200 ℃, cov xov hlau rwb thaiv tsev yuav mos heev. Thaum raug lub zog sab nraud nias lossis sib tsoo, nws yuav ua rau cov xov hlau txiav thiab luv luv.

C. Nws nyuaj rau tswj qhov sib txawv ntawm cov xim ntawm cov pawg. Cov teeb meem xws li khawb, ua kom dawb thiab cov cim luam tawm tev tawm feem ntau tshwm sim thaum lub sijhawm ua tiav.

D. Cov rwb thaiv tsev XLPE nrog qib tiv taus kub ntawm 150 ℃ yog tsis muaj halogen kiag li thiab tuaj yeem dhau qhov kev sim hluav taws xob VW-1 raws li cov qauv UL1581, thaum tswj tau cov khoom siv kho tshuab thiab hluav taws xob zoo heev. Txawm li cas los xij, tseem muaj qee qhov kev txwv hauv kev siv tshuab tsim khoom thiab tus nqi siab.

3. Cov xov hlau roj hmab silicone thiab cov cables

Cov polymer molecule ntawm silicone roj hmab yog cov qauv saw hlau tsim los ntawm SI-O (silicon-oxygen) bonds. SI-O bond yog 443.5KJ / MOL, uas yog siab dua li CC bond zog (355KJ / MOL). Feem ntau cov xov hlau thiab cov cables silicone roj hmab yog tsim los ntawm kev extrusion txias thiab cov txheej txheem kub vulcanization. Ntawm ntau yam xov hlau thiab cov cables roj hmab hluavtaws, vim nws cov qauv molecular tshwj xeeb, silicone roj hmab muaj kev ua tau zoo dua li lwm cov roj hmab ib txwm muaj.

A. Nws mos heev, muaj qhov elasticity zoo, tsis muaj ntxhiab thiab tsis muaj tshuaj lom, thiab tsis ntshai qhov kub siab thiab tuaj yeem tiv taus qhov txias heev. Qhov kub ua haujlwm yog txij li -90 txog 300 ℃. Cov roj hmab silicone muaj kev tiv taus cua sov zoo dua li cov roj hmab ib txwm. Nws tuaj yeem siv tas li ntawm 200 ℃ thiab rau lub sijhawm ntawm 350 ℃.

B. Tiv taus huab cua zoo heev. Txawm tias tom qab raug tshav ntuj ultraviolet thiab lwm yam huab cua ntev ntev los lawm, nws cov khoom siv lub cev tsuas yog hloov me ntsis xwb.

C. Cov roj hmab silicone muaj qhov tsis kam siab heev thiab nws qhov kev tiv thaiv tseem ruaj khov rau ntau qhov kub thiab txias.

Lub caij no, cov roj hmab silicone muaj kev tiv thaiv zoo heev rau kev tso tawm corona siab thiab kev tso tawm arc. Cov xov hlau thiab cov cables uas muaj cov roj hmab silicone muaj cov txiaj ntsig saum toj no thiab siv dav hauv cov xov hlau hluav taws xob siab rau cov TV, cov xov hlau tiv taus kub siab rau cov qhov cub microwave, cov xov hlau rau cov lauj kaub induction, cov xov hlau rau cov lauj kaub kas fes, cov xov hlau rau cov teeb, cov khoom siv UV, cov teeb halogen, cov xov hlau txuas sab hauv rau cov qhov cub thiab kiv cua, tshwj xeeb tshaj yog hauv cov khoom siv hauv tsev me me.

Txawm li cas los xij, qee qhov tsis zoo ntawm nws kuj txwv nws txoj kev siv dav dua. Piv txwv li:

A. Tsis tshua muaj zog tiv taus kua muag. Thaum lub sijhawm ua lossis siv, nws yuav raug puas tsuaj vim yog lub zog sab nraud nias, khawb thiab sib tsoo, uas yuav ua rau luv luv Circuit Court. Kev tiv thaiv tam sim no yog ntxiv ib txheej ntawm cov iav fiber lossis cov polyester fiber kub siab braided sab nraum cov rwb thaiv tsev silicone. Txawm li cas los xij, thaum lub sijhawm ua, nws tseem tsim nyog kom tsis txhob raug mob los ntawm lub zog sab nraud nias ntau li ntau tau.

B. Tus neeg sawv cev vulcanizing tam sim no feem ntau siv hauv vulcanization molding yog ob npaug, ob, plaub. Tus neeg sawv cev vulcanizing no muaj chlorine. Cov neeg sawv cev vulcanizing uas tsis muaj halogen kiag li (xws li platinum vulcanizing) muaj cov kev cai nruj rau qhov kub ntawm ib puag ncig thiab kim heev. Yog li ntawd, thaum ua cov xov hlau harnesses, cov ntsiab lus hauv qab no yuav tsum tau sau tseg: lub siab ntawm lub log siab yuav tsum tsis txhob siab dhau. Nws yog qhov zoo tshaj plaws los siv cov khoom siv roj hmab los tiv thaiv kev tawg thaum lub sijhawm tsim khoom, uas yuav ua rau tsis muaj kev tiv thaiv siab.

4. Cov hlua khi ethylene propylene diene monomer (EPDM) roj hmab (XLEPDM)

Cov roj hmab EPDM uas muaj cov roj hmab sib txuas ua ke yog cov roj hmab terpolymer ntawm ethylene, propylene thiab cov diene uas tsis sib txuas, uas tau sib txuas los ntawm cov tshuaj lom neeg lossis cov txheej txheem irradiation. Cov roj hmab EPDM uas muaj cov roj hmab sib txuas ua ke muaj cov txiaj ntsig ntawm ob qho tib si polyolefin insulated hlau thiab cov roj hmab ib txwm insulated hlau:

A. Mos, yoog tau, ywj ywj, tsis lo rau qhov kub siab, tiv taus kev laus mus sij hawm ntev, thiab tiv taus huab cua hnyav (-60 txog 125 ℃).

B. Tsis kam rau ozone, tsis kam rau UV, tsis kam rau hluav taws xob rwb thaiv tsev, thiab tsis kam rau tshuaj lom neeg.

C. Qhov tsis kam ntawm roj thiab cov kuab tshuaj zoo ib yam li cov rwb thaiv tsev roj hmab chloroprene dav dav. Nws yog ua los ntawm cov khoom siv extrusion kub ib txwm thiab kev sib txuas irradiation tau txais, uas yooj yim rau kev ua thiab pheej yig. Cov xov hlau cross-linked ethylene propylene diene monomer (EPDM) roj hmab rwb thaiv tsev muaj ntau qhov zoo saum toj no thiab siv dav hauv cov teb xws li cov xov hlau compressor tub yees, cov xov hlau motor tsis muaj dej, cov xov hlau transformer, cov xov hlau mobile hauv cov mines, drilling, tsheb, cov khoom siv kho mob, nkoj, thiab cov xov hlau sab hauv dav dav ntawm cov khoom siv hluav taws xob.

Cov qhov tsis zoo ntawm cov xov hlau XLEPDM yog:

A. Ib yam li cov xov hlau XLPE thiab PVC, nws tsis tshua muaj zog tiv taus kua muag.

B. Kev nplaum tsis zoo thiab kev nplaum tus kheej tsis zoo cuam tshuam rau kev ua tiav tom qab.

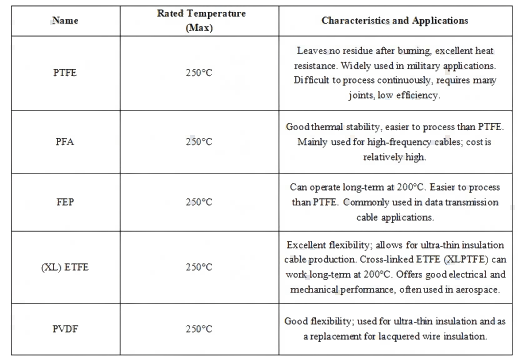

5. Cov xov hlau thiab cov cables uas muaj fluoroplastic

Piv nrog cov polyethylene thiab polyvinyl chloride cables, fluoroplastic cables muaj cov yam ntxwv tseem ceeb hauv qab no:

A. Cov fluoroplastics uas tiv taus kub siab muaj kev ruaj khov thermal zoo kawg nkaus, ua rau cov cables fluoroplastic hloov kho rau qhov kub siab xws li 150 txog 250 degrees Celsius. Nyob rau hauv cov xwm txheej ntawm cov conductors nrog tib thaj tsam hla-sectional, cov cables fluoroplastic tuaj yeem xa cov tam sim no loj dua, yog li nthuav dav ntau yam kev siv ntawm hom hlau insulated no. Vim yog qhov tshwj xeeb no, cov cables fluoroplastic feem ntau siv rau kev txuas hluav taws xob sab hauv thiab cov hlau txhuas hauv dav hlau, nkoj, lub cub tawg kub siab, thiab cov khoom siv hluav taws xob.

B. Kev tiv thaiv hluav taws zoo: Cov fluoroplastics muaj cov pa oxygen siab, thiab thaum hlawv, qhov sib kis hluav taws me me, tsim cov pa luam yeeb tsawg dua. Cov hlau ua los ntawm nws yog qhov tsim nyog rau cov cuab yeej thiab cov chaw uas muaj cov kev cai nruj rau kev tiv thaiv hluav taws. Piv txwv li: cov khoos phis tawj network, subways, tsheb, cov tsev siab thiab lwm qhov chaw pej xeem, thiab lwm yam. Thaum muaj hluav taws kub, tib neeg tuaj yeem muaj sijhawm khiav tawm yam tsis raug ntaus los ntawm cov pa luam yeeb tuab, yog li tau txais lub sijhawm cawm neeg zoo.

C. Kev ua tau zoo heev ntawm hluav taws xob: Piv nrog polyethylene, fluoroplastics muaj qhov dielectric tsis tu ncua qis dua. Yog li ntawd, piv nrog cov cables coaxial ntawm cov qauv zoo sib xws, fluoroplastic cables muaj qhov attenuation tsawg dua thiab tsim nyog dua rau kev xa cov teeb liab zaus siab. Niaj hnub no, kev siv cable ntau ntxiv tau dhau los ua ib qho kev hloov pauv. Lub caij no, vim muaj kev tiv thaiv kub siab ntawm fluoroplastics, lawv feem ntau siv ua cov xov hlau sab hauv rau cov khoom siv kis thiab kev sib txuas lus, jumpers ntawm cov khoom xa xov wireless thiab cov transmitters, thiab cov cables video thiab audio. Tsis tas li ntawd, fluoroplastic cables muaj lub zog dielectric zoo thiab kev tiv thaiv rwb thaiv tsev, ua rau lawv tsim nyog rau kev siv ua cov cables tswj rau cov twj paj nruag tseem ceeb thiab meters.

D. Cov khoom siv kho tshuab thiab tshuaj lom neeg zoo meej: Fluoroplastics muaj lub zog sib txuas tshuaj lom neeg siab, ruaj khov siab, yuav luag tsis cuam tshuam los ntawm kev hloov pauv kub, thiab muaj kev tiv taus kev laus ntawm huab cua thiab lub zog kho tshuab zoo heev. Thiab nws tsis cuam tshuam los ntawm ntau yam kua qaub, alkalis thiab cov kuab tshuaj organic. Yog li ntawd, nws tsim nyog rau cov chaw uas muaj kev hloov pauv huab cua tseem ceeb thiab cov xwm txheej corrosive, xws li petrochemicals, kev ua roj refining, thiab kev tswj cov cuab yeej siv roj.

E. Pab txhawb kev sib txuas vuam Hauv cov cuab yeej hluav taws xob, ntau qhov kev sib txuas yog ua los ntawm kev vuam. Vim tias qhov chaw yaj qis ntawm cov yas dav dav, lawv feem ntau yaj yooj yim ntawm qhov kub siab, xav tau kev txawj vuam zoo. Ntxiv mus, qee qhov chaw vuam xav tau qee lub sijhawm vuam, uas kuj yog qhov laj thawj vim li cas cov xov hlau fluoroplastic thiaj li nrov. Xws li cov xov hlau sab hauv ntawm cov khoom siv sib txuas lus thiab cov cuab yeej hluav taws xob.

Tau kawg, fluoroplastics tseem muaj qee qhov tsis zoo uas txwv lawv txoj kev siv:

A. Tus nqi ntawm cov khoom siv raw khoom kim heev. Tam sim no, kev tsim khoom hauv tsev tseem vam khom rau kev xa khoom tuaj (Daikin ntawm Nyiv Pooj thiab DuPont ntawm Tebchaws Meskas). Txawm hais tias cov fluoroplastics hauv tsev tau tsim kho sai sai hauv xyoo tas los no, cov hom kev tsim khoom tseem yog ib qho. Piv nrog cov khoom siv xa tuaj, tseem muaj qee qhov sib txawv hauv kev ruaj khov thermal thiab lwm yam khoom ntawm cov khoom siv.

B. Piv nrog rau lwm cov ntaub ntawv rwb thaiv tsev, cov txheej txheem tsim khoom nyuaj dua, qhov ua tau zoo ntawm kev tsim khoom qis, cov cim luam tawm feem ntau poob, thiab qhov poob loj, uas ua rau tus nqi tsim khoom siab dua.

Xaus lus, kev siv txhua hom khoom siv rwb thaiv tsev uas tau hais los saum toj no, tshwj xeeb tshaj yog cov khoom siv rwb thaiv tsev kub tshwj xeeb uas muaj qhov kub thiab txias tshaj 105 ℃, tseem nyob rau lub sijhawm hloov pauv hauv Suav teb. Txawm hais tias nws yog kev tsim cov hlau lossis kev ua cov hlau siv, tsis yog tsuas yog muaj cov txheej txheem paub tab xwb, tab sis kuj yog cov txheej txheem ntawm kev nkag siab txog qhov zoo thiab qhov tsis zoo ntawm hom hlau no.

Lub sijhawm tshaj tawm: Tsib Hlis-27-2025