1. Txheej txheem cej luam

Nrog rau kev loj hlob sai ntawm cov ntaub ntawv thiab kev sib txuas lus thev naus laus zis, cov xov hlau kho qhov muag, ua lub hauv paus tseem ceeb ntawm kev xa cov ntaub ntawv niaj hnub no, muaj cov kev xav tau siab dua rau kev ua tau zoo thiab zoo.Polybutylene terephthalate (PBT), ua ib lub thermoplastic engineering plastic nrog kev ua tau zoo heev, ua lub luag haujlwm tseem ceeb hauv kev tsim cov optical cables. PBT yog tsim los ntawm condensation polymerization ntawm dimethyl terephthalate (DMT) lossis terephthalic acid (TPA) thiab butanediol tom qab esterification. Nws yog ib qho ntawm tsib lub hom phiaj engineering plastics thiab tau tsim los ntawm GE thiab industrialized hauv xyoo 1970. Txawm hais tias nws pib lig dhau, nws tau tsim sai heev. Vim nws qhov kev ua tau zoo heev, kev ua haujlwm muaj zog thiab kev ua tau zoo, nws yog siv dav hauv cov khoom siv hluav taws xob, tsheb, kev sib txuas lus, cov khoom siv hauv tsev thiab lwm yam teb. Tshwj xeeb tshaj yog hauv kev tsim cov optical cables, nws yog siv rau hauv kev tsim cov optical fiber xoob raj thiab yog ib hom khoom siv cable ua tau zoo hauv cov ntaub ntawv raw ntawm optical cables.

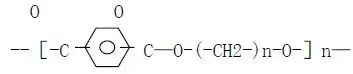

PBT yog ib hom polyester semi-pob tshab uas muaj xim dawb thiab tsis pom tseeb, nws tiv taus cua sov zoo heev thiab ruaj khov thaum ua cov khoom. Nws cov qauv molecular yog [(CH₂)₄OOCC₆H₄COO]n. Piv nrog PET, nws muaj ob pawg methylene ntxiv hauv cov saw hlau, ua rau nws cov saw hlau tseem ceeb muaj cov qauv helical thiab yooj ywm dua. PBT tsis tiv taus cov kua qaub thiab cov alkalis muaj zog, tab sis tuaj yeem tiv taus feem ntau cov kuab tshuaj organic thiab yuav lwj thaum kub siab. Vim nws cov khoom zoo heev, kev ruaj khov tshuaj lom neeg thiab kev ua haujlwm zoo, PBT tau dhau los ua cov khoom siv zoo tshaj plaws hauv kev lag luam cable optical thiab siv dav hauv ntau yam khoom PBT rau cov cables sib txuas lus thiab cov cables optical.

2. Cov yam ntxwv ntawm cov ntaub ntawv PBT

PBT feem ntau yog siv rau hauv daim ntawv ntawm kev sib xyaw ua ke. Los ntawm kev ntxiv cov tshuaj tiv thaiv hluav taws, cov neeg sawv cev txhawb nqa thiab lwm txoj kev hloov kho, nws qhov kev tiv taus cua sov, kev rwb thaiv hluav taws xob thiab kev hloov pauv ua tiav tuaj yeem txhim kho ntxiv. PBT muaj lub zog kho tshuab siab, zoo toughness thiab hnav tsis kam, thiab tuaj yeem tiv thaiv cov fibers optical hauv cov cable optical los ntawm kev puas tsuaj los ntawm kev ntxhov siab. Raws li ib qho ntawm cov khoom siv raw rau cov cables optical, PBT resin ua kom ntseeg tau tias cov khoom siv cable optical muaj kev ywj pheej zoo thiab ruaj khov thaum tswj hwm lub zog ntawm cov qauv.

Lub caij no, nws muaj kev ruaj khov tshuaj lom neeg thiab tuaj yeem tiv taus ntau yam tshuaj corrosive, ua kom ntseeg tau tias kev ua haujlwm ruaj khov ntev ntawm cov xov hlau kho qhov muag hauv cov chaw nyuaj xws li av noo thiab ntsev tsuag. Cov khoom siv PBT muaj kev ruaj khov thermal zoo heev thiab tuaj yeem tswj tau qhov ua tau zoo txawm tias nyob rau hauv qhov chaw kub siab, ua rau nws tsim nyog rau kev siv cov xov hlau kho qhov muag hauv thaj chaw kub sib txawv. Nws muaj kev ua tiav zoo heev thiab tuaj yeem tsim los ntawm extrusion, txhaj tshuaj molding thiab lwm txoj kev. Nws yog qhov tsim nyog rau kev sib dhos cov xov hlau kho qhov muag ntawm ntau yam duab thiab cov qauv thiab yog cov yas engineering ua tau zoo siv dav hauv kev tsim cov xov hlau.

3. Kev siv PBT hauv Optical Cables

Hauv cov txheej txheem ntawm kev tsim cov xov hlau optical, PBT feem ntau yog siv rau hauv kev tsim cov raj xoob raucov fibers kho qhov muagNws lub zog siab thiab kev tawv tawv tuaj yeem txhawb nqa thiab tiv thaiv cov fibers optical, tiv thaiv kev puas tsuaj los ntawm cov yam ntxwv ntawm lub cev xws li khoov thiab ncab. Tsis tas li ntawd, cov khoom siv PBT muaj kev tiv thaiv cua sov zoo heev thiab kev ua haujlwm tiv thaiv kev laus, uas pab txhim kho kev ruaj khov thiab kev ntseeg siab ntawm cov cables optical thaum lub sijhawm ua haujlwm ntev. Nws yog ib qho ntawm cov khoom siv PBT tseem ceeb siv hauv cov cables optical tam sim no.

PBT kuj tseem siv ua lub plhaub sab nraud ntawm cov xov hluav taws xob optical. Lub plhaub tsis yog tsuas yog yuav tsum muaj lub zog kho tshuab kom daws tau qhov kev hloov pauv ntawm qhov chaw sab nraud, tab sis kuj yuav tsum muaj kev tiv thaiv kev hnav zoo heev, kev tiv thaiv kev xeb tshuaj lom neeg thiab kev laus UV kom ntseeg tau tias lub neej ua haujlwm ntawm cov xov hluav taws xob optical thaum tso sab nraum zoov, hauv qhov chaw ntub dej lossis dej hiav txwv. Lub plhaub cable optical muaj qhov yuav tsum tau ua siab rau kev ua haujlwm thiab kev hloov pauv ib puag ncig ntawm PBT, thiab PBT resin qhia tau tias muaj kev sib raug zoo ntawm daim ntawv thov.

Hauv cov kab ke sib txuas ntawm cov xov hlau kho qhov muag, PBT kuj tseem siv tau los tsim cov khoom tseem ceeb xws li cov thawv sib txuas. Cov khoom no yuav tsum ua tau raws li cov kev cai nruj rau kev kaw, kev tiv thaiv dej thiab kev tiv thaiv huab cua. Cov khoom siv PBT, nrog nws cov khoom zoo heev thiab kev ruaj khov ntawm cov qauv, yog qhov kev xaiv tsim nyog heev thiab ua lub luag haujlwm tseem ceeb hauv cov khoom siv raw ntawm cov xov hlau kho qhov muag.

4. Kev Ceev Faj Txog Kev Ua Khoom

Ua ntej txhaj tshuaj molding, PBT yuav tsum tau ziab ntawm 110 ℃ txog 120 ℃ li 3 teev kom tshem tawm cov dej noo uas nqus tau thiab zam kev tsim cov npuas lossis brittleness thaum lub sijhawm ua. Qhov kub molding yuav tsum tau tswj ntawm 250 ℃ thiab 270 ℃, thiab qhov kub pwm raug pom zoo kom tswj ntawm 50 ℃ txog 75 ℃. Vim tias qhov kub hloov iav ntawm PBT tsuas yog 22 ℃ thiab qhov txias crystallization ceev, nws lub sijhawm txias luv luv. Thaum lub sijhawm txhaj tshuaj molding, nws yog qhov tsim nyog los tiv thaiv qhov kub ntawm lub nozzle kom tsis txhob qis dhau, uas yuav ua rau cov dej ntws raug thaiv. Yog tias qhov kub ntawm lub thoob tshaj 275 ℃ lossis cov khoom siv molten nyob ntev dhau, nws yuav ua rau thermal degradation thiab embrittlement.

Nws raug pom zoo kom siv lub rooj vag loj dua rau kev txhaj tshuaj. Lub kaw lus khiav kub yuav tsum tsis txhob siv. Lub pwm yuav tsum tswj tau qhov ua pa tawm zoo. Cov ntaub ntawv PBT sprue uas muaj cov tshuaj tua hluav taws lossis cov iav fiber reinforcement tsis pom zoo kom rov siv dua kom tsis txhob muaj kev puas tsuaj ntawm kev ua haujlwm. Thaum lub tshuab raug kaw, lub thoob yuav tsum tau ntxuav nrog PE lossis PP cov khoom siv kom tiv thaiv kev ua kom cov khoom seem. Cov txheej txheem ua tiav no muaj qhov tseem ceeb rau cov chaw tsim khoom siv kho qhov muag cable raw hauv kev tsim cov khoom siv cable loj.

5. Cov txiaj ntsig ntawm daim ntawv thov

Kev siv PBT hauv cov xov hluav taws xob tau ua rau cov xov hluav taws xob ua haujlwm tau zoo dua qub. Nws lub zog siab thiab kev tawv nqaij ua rau cov xov hluav taws xob tiv taus kev cuam tshuam thiab kev qaug zog, thiab ua rau nws lub neej ua haujlwm ntev dua. Lub caij no, cov khoom siv PBT zoo heev tau ua rau kev tsim khoom zoo dua thiab txo cov nqi tsim khoom. Qhov zoo tshaj plaws tiv thaiv kev laus thiab kev xeb ntawm cov tshuaj ua rau nws ua haujlwm ruaj khov ntev hauv qhov chaw nyuaj, ua rau kev ntseeg siab thiab kev saib xyuas ntawm cov khoom zoo dua.

Ua ib pawg tseem ceeb hauv cov khoom siv raw ntawm cov xov hluav taws xob, PBT resin ua lub luag haujlwm hauv ntau qhov kev sib txuas thiab yog ib qho ntawm cov thermoplastic engineering plastics uas cov chaw tsim khoom siv hluav taws xob muab qhov tseem ceeb thaum xaiv cov ntaub ntawv cable.

6. Cov Lus Xaus thiab Kev Cia Siab

PBT tau dhau los ua ib yam khoom tseem ceeb hauv kev tsim cov khoom siv hluav taws xob vim nws muaj kev ua tau zoo heev hauv cov khoom siv kho tshuab, kev ruaj khov thermal, kev tiv thaiv corrosion thiab kev ua haujlwm. Yav tom ntej, thaum kev lag luam sib txuas lus optical txuas ntxiv mus, cov kev cai siab dua yuav raug muab tso rau pem hauv ntej rau kev ua haujlwm ntawm cov khoom siv. Kev lag luam PBT yuav tsum txhawb nqa kev tsim kho tshiab thiab kev tiv thaiv ib puag ncig ntsuab, txhim kho nws cov kev ua tau zoo thiab kev tsim khoom zoo. Thaum ua tau raws li cov kev cai ua tau zoo, txo kev siv hluav taws xob thiab cov nqi khoom siv yuav pab PBT ua lub luag haujlwm tseem ceeb hauv cov khoom siv hluav taws xob thiab ntau yam kev siv.

Lub sijhawm tshaj tawm: Lub Rau Hli-30-2025