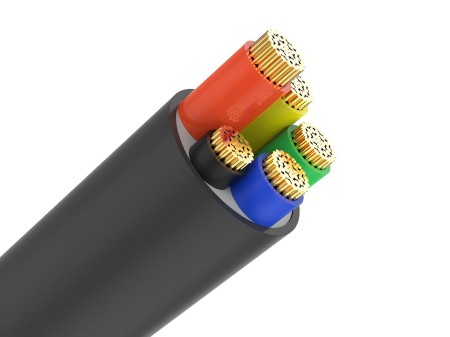

Cov txheej txheem hluav taws xob niaj hnub no vam khom kev sib txuas ntawm cov khoom siv sib txawv, cov laug cam hluav taws xob, thiab cov khoom siv sab nraud. Txawm hais tias xa hluav taws xob lossis cov teeb liab hluav taws xob, cov xov hlau yog lub hauv paus ntawm kev sib txuas xov hlau, ua rau lawv yog ib feem tseem ceeb ntawm txhua lub tshuab.

Txawm li cas los xij, qhov tseem ceeb ntawm cov tsho cable (txheej sab nraud uas nyob ib puag ncig thiab tiv thaiv cov neeg hlau sab hauv) feem ntau raug saib tsis taus. Kev xaiv cov khoom siv tsho cable zoo yog qhov kev txiav txim siab tseem ceeb hauv kev tsim thiab tsim cov cable, tshwj xeeb tshaj yog thaum siv rau hauv qhov chaw ib puag ncig hnyav. Kev nkag siab txog qhov sib npaug ntawm kev ua haujlwm ntawm cov khoom siv, kev tiv thaiv ib puag ncig, kev ywj pheej, tus nqi, thiab kev ua raws li txoj cai yog qhov tseem ceeb rau kev xaiv zoo.

Hauv plawv ntawm lub tsho cable yog ib daim ntaub thaiv uas tiv thaiv thiab ua kom lub cable sab hauv siv tau ntev thiab ntseeg tau. Qhov kev tiv thaiv no tiv thaiv cov dej noo, tshuaj lom neeg, hluav taws xob UV, thiab kev ntxhov siab ntawm lub cev xws li kev puas tsuaj thiab kev cuam tshuam.

Cov khoom siv rau cov tsho cable yog los ntawm cov yas yooj yim mus rau cov polymers siab heev, txhua tus muaj cov yam ntxwv tshwj xeeb kom ua tau raws li cov kev xav tau ib puag ncig thiab kev kho tshuab. Cov txheej txheem xaiv yog qhov tseem ceeb vim tias cov khoom siv zoo ua kom muaj kev ua tau zoo tshaj plaws thiab kev tiv thaiv raws li cov xwm txheej siv.

Tsis muaj ib txoj kev daws teeb meem uas "ib qho loj me haum rau txhua tus" rau cov tsho cable. Cov khoom siv xaiv tuaj yeem sib txawv heev nyob ntawm qhov xwm txheej tshwj xeeb ntawm daim ntawv thov.

Muaj ntau yam uas yuav tsum xav txog thaum xaiv cov khoom siv cable tsho zoo.

1. Tej yam ib puag ncig

Kev tiv thaiv tshuaj lom neeg yog ib qho tseem ceeb hauv kev xaiv cov tsho cable, vim tias cov cables yuav ntsib cov roj, cov kuab tshuaj, cov kua qaub, lossis cov hauv paus, nyob ntawm lawv daim ntawv thov. Lub tsho cable uas tau xaiv zoo tuaj yeem tiv thaiv kev puas tsuaj lossis xeb ntawm nws cov khoom hauv qab, yog li tswj kev ncaj ncees ntawm cov cable thoob plaws nws lub neej kev pabcuam. Piv txwv li, hauv cov chaw ua haujlwm uas muaj kev raug tshuaj lom neeg ntau, nws yog ib qho tseem ceeb rau kev xaiv cov ntaub ntawv uas tuaj yeem tiv taus cov xwm txheej hnyav no. Ntawm no, cov tshuaj lom neeg tshwj xeeb uas cov cable yuav raug yuav tsum tau soj ntsuam, vim qhov no txiav txim siab qhov xav tau cov ntaub ntawv tshwj xeeb xws li fluoropolymers kom ua tiav kev tiv thaiv tshuaj lom neeg heev.

Kev tiv thaiv huab cua thiab lub hnub ci yog lwm qhov tseem ceeb uas yuav tsum xav txog, tshwj xeeb tshaj yog rau cov cables siv sab nraum zoov. Kev raug tshav ntuj ntev ntev tuaj yeem ua rau cov khoom siv ib txwm tsis muaj zog, ua rau brittleness thiab thaum kawg ua tsis tiav. Cov ntaub ntawv tsim los tiv thaiv UV hluav taws xob ua kom ntseeg tau tias cov cable tseem ua haujlwm tau zoo thiab ruaj khov txawm tias nyob hauv tshav ntuj hnyav. Rau cov ntawv thov zoo li no, cov ntaub ntawv zoo tagnrho yog CPE thermoplastics, CPE thermostats, lossis EPR thermostats. Lwm cov ntaub ntawv siab heev, xws li cross-linked polyethylene (XLPE), tau tsim los muab kev tiv thaiv UV zoo dua, ua kom lub cable siv tau ntev hauv kev siv sab nraum zoov.

Tsis tas li ntawd xwb, nyob rau hauv ib puag ncig uas muaj kev pheej hmoo ntawm hluav taws, kev xaiv lub tsho cable uas tsis ua rau hluav taws kub lossis tua tus kheej tuaj yeem yog qhov kev xaiv cawm txoj sia. Cov ntaub ntawv no yog tsim los tiv thaiv kev kis ntawm cov nplaim taws, ntxiv ib txheej tseem ceeb ntawm kev nyab xeeb hauv cov ntawv thov tseem ceeb. Rau kev ua kom hluav taws kub, cov kev xaiv zoo heev suav nrogPVCcov thermoplastics thiab CPE thermoplastics. Cov ntaub ntawv no tuaj yeem ua rau qeeb qeeb ntawm cov nplaim taws thaum txo cov pa roj lom thaum lub sijhawm hlawv.

2. Cov Khoom Siv Kho Tshuab

Qhov kev tiv taus kev sib txhuam, lub zog cuam tshuam, thiab lub peev xwm tsoo ntawm lub tsho cable cuam tshuam ncaj qha rau qhov ruaj khov ntawm polyurethane. Qhov no yog qhov tsim nyog tshaj plaws hauv cov ntawv thov uas lub cable hla dhau thaj chaw nyuaj lossis xav tau kev tuav ntau zaus. Hauv cov ntawv thov txawb heev, xws li hauv robotics lossis tshuab dynamic, kev xaiv lub tsho cable nrog cov khoom siv kho tshuab zoo dua tuaj yeem pab zam kev hloov pauv thiab kev saib xyuas ntau zaus. Cov ntaub ntawv zoo tshaj plaws uas tiv taus kev hnav rau lub tsho npog suav nrog polyurethane thermoplastics thiab CPE thermoplastics.

3. Kev Xav Txog Kub

Qhov kub thiab txias ntawm cov khoom siv cable tsho tuaj yeem yog qhov sib txawv ntawm kev ua tiav lossis kev ua tsis tiav rau ib lub kaw lus. Cov ntaub ntawv uas tsis tuaj yeem tiv taus qhov kub thiab txias ntawm lawv qhov chaw xav tau yuav ua rau tawg yooj yim hauv cov xwm txheej txias lossis lwj thaum raug rau qhov kub siab. Qhov kev lwj no tuaj yeem ua rau lub cable puas tsuaj thiab ua rau kev rwb thaiv tsev hluav taws xob tsis ua haujlwm, ua rau muaj kev cuam tshuam kev ua haujlwm lossis kev phom sij rau kev nyab xeeb.

Txawm hais tias ntau cov cables txheem yuav raug ntsuas rau txog li 105 ° C, cov ntawv thov PVC tshwj xeeb yuav tsum tau tiv taus qhov kub siab dua. Rau cov lag luam xws li roj thiab roj av, cov ntawv thov tshwj xeeb xav tau cov ntaub ntawv, xws li ITT Cannon's SJS series cov ntaub ntawv, uas tuaj yeem tiv taus qhov kub txog li 200 ° C. Rau cov kub siab no, ntau yam khoom siv yuav tsum tau xav txog, suav nrog PVC ntawm sab thermoplastic thiab CPE lossis EPR lossis CPR ntawm sab thermostat. Cov ntaub ntawv uas tuaj yeem ua haujlwm hauv cov chaw zoo li no tuaj yeem tiv taus qhov kub siab thiab tiv taus kev laus thermal, ua kom ntseeg tau tias cov cable ua haujlwm tau zoo dhau sijhawm.

Xav txog cov chaw kub siab, xws li cov chaw khawb av hauv hiav txwv. Hauv cov chaw kub siab thiab kub siab no, nws yog ib qho tsim nyog los xaiv cov khoom siv cable uas tuaj yeem tiv taus qhov kub siab heev yam tsis muaj kev puas tsuaj lossis ua tsis tiav. Thaum kawg, kev xaiv cov khoom siv cable zoo tuaj yeem ua kom muaj kev nyab xeeb thiab txhim khu kev qha thaum lub sijhawm ntev ntawm cov khoom siv.

4. Qhov Xav Tau Kev Ywj Pheej

Qee daim ntawv thov yuav tsum tau cov cables kom nyob twj ywm ywj pheej nyob rau hauv kev khoov thiab ntswj rov qab. Qhov kev xav tau ntawm kev ywj pheej tsis txo qhov xav tau ntawm kev ruaj khov; yog li ntawd, cov ntaub ntawv yuav tsum tau xaiv kom zoo zoo kom sib npaug ob qhov kev xav tau no. Hauv cov xwm txheej no, cov ntaub ntawv xws li thermoplastic elastomers (TPE) lossis polyurethane (PUR) tau nyiam rau lawv qhov elasticity thiab resilience.

Piv txwv li, cov cables siv rau hauv kev lag luam automation yuav tsum muaj kev ywj pheej heev kom haum rau kev txav mus los ntawm cov tshuab xws li robots. Mesh robots siv rau cov haujlwm xws li kev khaws thiab tso cov khoom yog ib qho piv txwv zoo ntawm qhov xav tau no. Lawv tus qauv tsim tso cai rau ntau yam kev txav mus los, tso kev ntxhov siab tas li rau ntawm cov cables, tsim nyog siv cov ntaub ntawv uas tuaj yeem tiv taus kev khoov thiab ntswj yam tsis muaj kev cuam tshuam rau kev ua haujlwm.

Tom qab xav txog tej yam ib puag ncig, tej yam khoom siv, qhov kub thiab txias, thiab tej yam xav tau kev ywj pheej, nws tseem ceeb heev uas yuav tsum nco ntsoov tias lub txoj kab uas hla sab nraud ntawm lub cable yuav txawv nrog txhua yam khoom siv. Yuav kom nyob twj ywm zoo rau ib puag ncig, lub txoj kab uas hla ntawm lub cable yuav tsum nyob hauv qhov kev sib khi ntawm lub plhaub tom qab lossis lub qhov txuas.

Lub sijhawm tshaj tawm: Lub Yim Hli-12-2024