Thaum nrhiav cov cables thiab cov xov hlau zoo tshaj plaws, kev xaiv cov khoom siv sheathing zoo yog qhov tseem ceeb heev. Lub sheath sab nraud muaj ntau yam haujlwm los xyuas kom meej tias lub cable lossis hlau ruaj khov, kev nyab xeeb thiab kev ua tau zoo. Nws tsis yog qhov txawv txawv uas yuav tsum txiav txim siab ntawm polyurethane (PUR) thiabpolyvinyl chloride (PVC)Hauv tsab xov xwm no, koj yuav kawm txog qhov sib txawv ntawm kev ua tau zoo ntawm ob yam khoom thiab cov ntawv thov uas txhua yam khoom siv zoo tshaj plaws.

Cov qauv thiab kev ua haujlwm ntawm cov cables thiab cov xov hlau

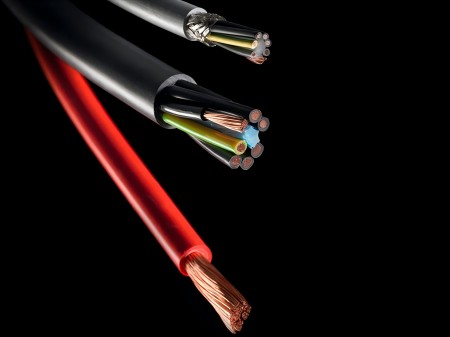

Ib lub plhaub (tseem hu ua lub plhaub sab nraud lossis lub plhaub) yog txheej sab nraud tshaj plaws ntawm cov xov hlau lossis hlau thiab siv los ntawm kev siv ib qho ntawm ntau txoj kev extrusion. Lub plhaub tiv thaiv cov xov hlau conductors thiab lwm yam khoom siv los ntawm cov yam ntxwv sab nraud xws li cua sov, txias, ntub dej lossis tshuaj lom neeg thiab kev cuam tshuam. Nws kuj tseem tuaj yeem kho cov duab thiab cov duab ntawm cov xov hlau stranded, nrog rau cov txheej tiv thaiv (yog tias muaj), yog li txo qis kev cuam tshuam nrog lub cable's electromagnetic compatibility (EMC). Qhov no yog qhov tseem ceeb kom ntseeg tau tias muaj kev sib kis ntawm lub zog, teeb liab, lossis cov ntaub ntawv hauv lub cable lossis hlau. Lub plhaub kuj tseem ua lub luag haujlwm tseem ceeb hauv kev ruaj khov ntawm cov xov hlau thiab hlau.

Kev xaiv cov ntaub thaiv zoo yog qhov tseem ceeb rau kev txiav txim siab qhov zoo tshaj plaws ntawm cov xov hlau rau txhua daim ntawv thov. Yog li ntawd, nws yog ib qho tseem ceeb kom paub meej tias lub cable lossis hlau yuav tsum ua haujlwm li cas thiab nws yuav tsum ua tau raws li qhov yuav tsum tau ua.

Cov ntaub ntawv sheathing feem ntau

Polyurethane (PUR) thiab polyvinyl chloride (PVC) yog ob yam khoom siv sheathing uas siv ntau tshaj plaws rau cov cables thiab xov hlau. Saib ntawm qhov muag, tsis muaj qhov sib txawv ntawm cov khoom no, tab sis lawv muaj cov yam ntxwv sib txawv uas ua rau lawv haum rau ntau yam kev siv. Tsis tas li ntawd, ntau lwm yam khoom siv tuaj yeem siv ua cov khoom sheathing, suav nrog cov roj hmab lag luam, thermoplastic elastomers (TPE), thiab cov yas tshwj xeeb. Txawm li cas los xij, vim tias lawv tsis tshua muaj ntau dua li PUR thiab PVC, peb tsuas yog yuav piv ob yam no yav tom ntej.

PUR - Qhov tseem ceeb tshaj plaws

Polyurethane (lossis PUR) yog hais txog ib pawg yas uas tau tsim nyob rau xyoo 1930s. Nws yog tsim los ntawm cov txheej txheem tshuaj hu ua kev sib ntxiv polymerization. Cov khoom siv raw feem ntau yog roj av, tab sis cov khoom siv cog xws li qos yaj ywm, pob kws lossis qab zib beets kuj tuaj yeem siv rau hauv nws cov khoom tsim. Polyurethane yog ib qho thermoplastic elastomer. Qhov no txhais tau tias lawv yoog tau thaum cua sov, tab sis tuaj yeem rov qab mus rau lawv cov duab qub thaum cua sov.

Polyurethane muaj cov khoom siv kho tshuab zoo heev. Cov khoom siv no muaj kev tiv thaiv kev hnav zoo heev, kev tiv thaiv kev txiav thiab kev tsim kua muag, thiab tseem yoog tau yooj yim txawm tias nyob rau qhov kub qis. Qhov no ua rau PUR tshwj xeeb tshaj yog rau cov ntawv thov uas xav tau kev txav mus los thiab kev khoov, xws li kev rub cov saw hlau. Hauv cov ntawv thov robotic, cov cables nrog PUR sheathing tuaj yeem tiv taus ntau lab lub voj voog khoov lossis lub zog torsional muaj zog yam tsis muaj teeb meem. PUR kuj muaj kev tiv thaiv zoo rau roj, cov kuab tshuaj thiab ultraviolet hluav taws xob. Tsis tas li ntawd, nyob ntawm cov khoom sib xyaw, nws yog halogen-dawb thiab nplaim taws retardant, uas yog cov qauv tseem ceeb rau cov cables uas tau ntawv pov thawj UL thiab siv hauv Tebchaws Meskas. PUR cables feem ntau siv rau hauv tshuab thiab Hoobkas tsim kho, kev lag luam automation, thiab kev lag luam tsheb.

PVC - qhov tseem ceeb tshaj plaws

Polyvinyl chloride (PVC) yog ib hom yas uas tau siv los ua cov khoom sib txawv txij li xyoo 1920. Nws yog cov khoom ntawm cov roj saw polymerization ntawm vinyl chloride. Tsis zoo li elastomer PUR, PVC yog ib qho thermoplastic polymer. Yog tias cov khoom raug deformed hauv cua sov, nws tsis tuaj yeem rov qab mus rau nws lub xeev qub.

Ua ib yam khoom siv sheathing, polyvinyl chloride muaj ntau yam kev xaiv vim nws muaj peev xwm hloov kho rau ntau yam kev xav tau los ntawm kev hloov nws cov khoom sib xyaw. Nws lub peev xwm thauj khoom tsis siab npaum li PUR, tab sis PVC kuj tseem pheej yig dua; Tus nqi nruab nrab ntawm polyurethane yog plaub npaug siab dua. Tsis tas li ntawd, PVC tsis muaj ntxhiab thiab tiv taus dej, kua qaub thiab cov neeg ua haujlwm ntxuav. Nws yog vim li no nws feem ntau siv hauv kev lag luam zaub mov lossis hauv cov chaw noo noo. Txawm li cas los xij, PVC tsis yog halogen-dawb, yog vim li cas nws thiaj li suav tias tsis haum rau cov ntawv thov sab hauv tsev. Tsis tas li ntawd, nws tsis yog roj resistant, tab sis cov khoom no tuaj yeem ua tiav los ntawm cov tshuaj ntxiv tshwj xeeb.

Xaus lus

Ob qho tib si polyurethane thiab polyvinyl chloride muaj lawv qhov zoo thiab qhov tsis zoo li cov ntaub ntawv cable thiab hlau sheathing. Tsis muaj lus teb meej rau cov khoom siv twg zoo tshaj plaws rau txhua daim ntawv thov; Ntau nyob ntawm tus kheej xav tau ntawm daim ntawv thov. Hauv qee kis, cov ntaub ntawv sheathing sib txawv kiag li yuav yog qhov kev daws teeb meem zoo dua. Yog li ntawd, peb txhawb kom cov neeg siv nrhiav kev qhia los ntawm cov kws tshaj lij uas paub txog cov khoom zoo thiab tsis zoo ntawm cov ntaub ntawv sib txawv thiab tuaj yeem ntsuas qhov hnyav ntawm ib leeg.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-20-2024