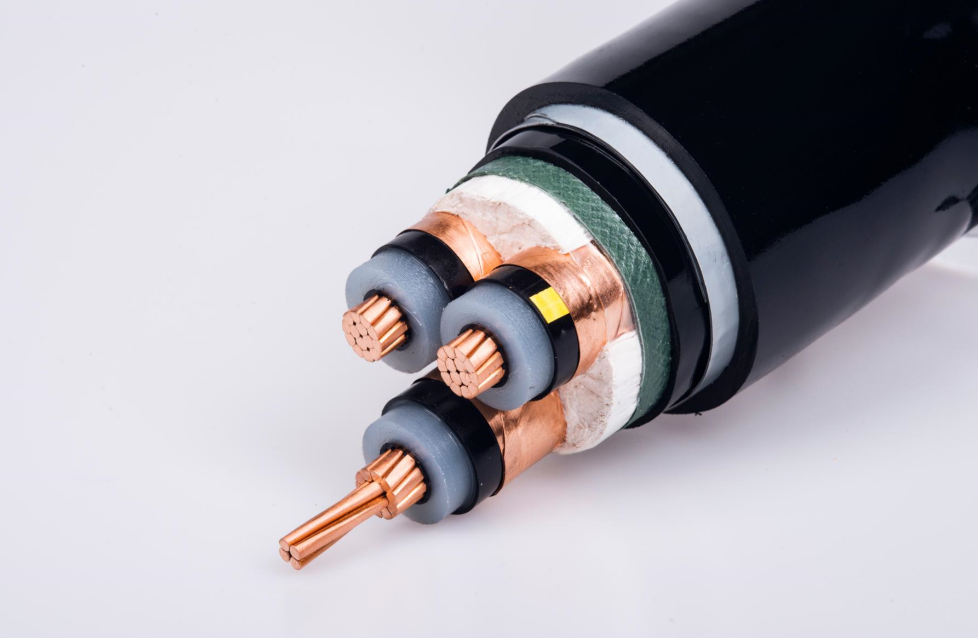

Cov txheej tiv thaiv hlau yog ib qho qauv tseem ceeb hauvcov xov hluav taws xob nruab nrab (3.6 / 6kV∽26 / 35kV) txuas nrog polyethylene-insulated fais fab cablesTsim cov qauv ntawm lub hlau tiv thaiv kom zoo, xam qhov luv luv tam sim no uas lub tiv thaiv yuav ris, thiab tsim cov txheej txheem ua haujlwm tiv thaiv kom zoo yog qhov tseem ceeb rau kev ua kom zoo ntawm cov xov hlau sib txuas thiab kev nyab xeeb ntawm tag nrho lub operating system.

Txheej Txheem Tiv Thaiv:

Cov txheej txheem tiv thaiv hauv kev tsim cov xov hluav taws xob nruab nrab yog qhov yooj yim heev. Txawm li cas los xij, yog tias tsis ua tib zoo saib xyuas qee cov ntsiab lus, nws tuaj yeem ua rau muaj kev cuam tshuam loj heev rau qhov zoo ntawm cov xov hlau.

1. Daim kab xev tooj liabTxheej Txheem Tiv Thaiv:

Daim kab xev tooj liab siv rau kev tiv thaiv yuav tsum yog daim kab xev tooj liab mos uas tau annealed tag nrho yam tsis muaj qhov tsis zoo xws li cov npoo nkhaus lossis tawg ntawm ob sab.Daim kab xev tooj liabqhov ntawd nyuaj dhau lawm tuaj yeem ua puas tsuaj rautxheej semiconductive, thaum daim kab xev uas mos dhau yuav yooj yim ntsws. Thaum lub sijhawm qhwv, nws yog ib qho tseem ceeb kom teeb tsa lub kaum sab xis qhwv kom raug, tswj qhov nruj kom raug kom tsis txhob nruj dhau. Thaum cov xov hlau muaj zog, kev rwb thaiv tsev tsim cua sov thiab nthuav dav me ntsis. Yog tias daim kab xev tooj liab qhwv nruj dhau, nws yuav nkag mus rau hauv lub tsho rwb thaiv tsev lossis ua rau daim kab xev tawg. Cov ntaub mos mos yuav tsum tau siv ua padding rau ob sab ntawm lub tshuab tiv thaiv lub tshuab nqa-up reel kom tiv thaiv kev puas tsuaj rau daim kab xev tooj liab thaum lub sijhawm tom ntej hauv cov txheej txheem. Cov pob qij txha ntawm daim kab xev tooj liab yuav tsum tau vuam qhov chaw, tsis txhob soldered, thiab yeej tsis txuas nrog siv cov plugs, daim kab xev nplaum, lossis lwm txoj hauv kev tsis yog tus qauv.

Nyob rau hauv cov ntaub ntawv ntawm tooj liab daim kab xev shielding, kev sib cuag nrog lub semiconductive txheej yuav ua rau muaj oxide tsim vim yog qhov chaw sib cuag, txo qhov siab sib cuag thiab ob npaug ntawm kev sib cuag thaum lub hlau shielding txheej dhau los ntawm thermal nthuav dav lossis contraction thiab bending. Kev sib cuag tsis zoo thiab thermal nthuav dav yuav ua rau muaj kev puas tsuaj ncaj qha rau sab nraudtxheej semiconductive. Kev sib cuag kom zoo ntawm daim kab xev tooj liab thiab txheej semiconductive yog qhov tseem ceeb kom ntseeg tau tias muaj kev sib txuas hauv av zoo. Kev kub dhau, vim yog kev nthuav dav thermal, yuav ua rau daim kab xev tooj liab nthuav dav thiab deform, ua rau txheej semiconductive puas tsuaj. Hauv cov xwm txheej zoo li no, daim kab xev tooj liab uas txuas tsis zoo lossis vuam tsis raug tuaj yeem nqa cov hluav taws xob them los ntawm qhov kawg tsis tau sib txuas mus rau qhov kawg uas tau sib txuas, ua rau kub dhau thiab laus sai ntawm txheej semiconductive ntawm qhov chaw uas daim kab xev tooj liab tawg.

2. Cov Txheej Txheem Tiv Thaiv Hlau Tooj Liab:

Thaum siv cov hlau tooj liab uas tsis muaj qhov txhab, kev qhwv cov hlau tooj liab ncaj qha ncig lub ntsej muag sab nraud tuaj yeem ua rau qhwv nruj, ua rau lub rwb thaiv tsev puas tsuaj thiab ua rau cov xov hlau tawg. Txhawm rau daws qhov teeb meem no, nws yog qhov tsim nyog los ntxiv 1-2 txheej ntawm daim kab xev nylon semiconductive ncig lub txheej txheej sab nraud extruded semiconductive tom qab extrusion.

Cov xov hlau uas siv cov xov hlau tooj liab uas tsis muaj qhov txhab tsis raug kev txom nyem los ntawm kev tsim oxide pom ntawm cov txheej txheej tooj liab. Cov xov hlau tooj liab uas tiv thaiv muaj qhov khoov tsawg kawg nkaus, me ntsis kev hloov pauv ntawm kev nthuav dav thermal, thiab me ntsis kev nce ntxiv ntawm kev tiv taus kev sib cuag, tag nrho cov no pab txhawb rau kev ua haujlwm hluav taws xob, tshuab, thiab thermal hauv kev ua haujlwm cable.

Lub sijhawm tshaj tawm: Lub Kaum Hli-27-2023