Abstract: Lub hauv paus ntsiab lus ntawm kev sib txuas, kev faib tawm, kev tsim, cov txheej txheem thiab cov khoom siv ntawm silane cross-linked polyethylene insulating khoom rau xaim thiab cable tau piav qhia luv luv, thiab qee yam ntxwv ntawm silane naturally cross-linked polyethylene insulating khoom hauv daim ntawv thov thiab siv nrog rau cov yam ntxwv cuam tshuam rau qhov xwm txheej ntawm cov khoom siv tau qhia.

Cov Lus Tseem Ceeb: Silane cross-linking; Natural cross-linking; Polyethylene; Rwb Thaiv Tsev; Hlau thiab cable

Cov khoom siv cable silane cross-linked polyethylene tam sim no siv dav hauv kev lag luam hlau thiab cable ua cov khoom siv rwb thaiv tsev rau cov xov hluav taws xob qis. Cov khoom siv hauv kev tsim cov xov hlau thiab cable, thiab peroxide cross-linking thiab irradiation cross-linking piv rau cov khoom siv tsim khoom xav tau yog yooj yim, yooj yim rau kev khiav lag luam, tus nqi qis thiab lwm yam zoo, tau dhau los ua cov khoom siv tseem ceeb rau cov xov hlau qis-voltage cross-linked nrog rwb thaiv tsev.

1. Silane cross-linked cable khoom siv cross-linking txoj cai

Muaj ob txoj kev tseem ceeb uas koom nrog kev ua cov polyethylene silane cross-linked: grafting thiab cross-linking. Hauv cov txheej txheem grafting, cov polymer poob nws cov H-atom ntawm cov pa roj carbon tertiary nyob rau hauv qhov kev ua ntawm tus pib dawb thiab pyrolysis rau hauv cov dawb radicals, uas ua rau muaj kev cuam tshuam nrog pawg - CH = CH2 ntawm vinyl silane los tsim cov polymer grafted uas muaj pawg trioxysilyl ester. Hauv cov txheej txheem cross-linking, cov polymer graft yog thawj hydrolysed nyob rau hauv qhov muaj dej los tsim silanol, thiab - OH condenses nrog pawg Si-OH sib ze los tsim cov Si-O-Si bond, yog li cross-linking cov polymer macromolecules.

2. Cov khoom siv cable txuas nrog Silane thiab nws txoj kev tsim cov cable

Raws li koj paub, muaj ob kauj ruam thiab ib kauj ruam tsim cov xov hlau silane cross-linked thiab lawv cov xov hlau. Qhov sib txawv ntawm ob kauj ruam thiab ib kauj ruam yog nyob rau hauv qhov chaw uas cov txheej txheem silane grafting raug ua tiav, cov txheej txheem grafting ntawm lub chaw tsim khoom siv cable rau txoj kev ob kauj ruam, cov txheej txheem grafting hauv lub Hoobkas tsim cable rau txoj kev ib kauj ruam. Cov khoom siv polyethylene insulating silane cross-linked ob kauj ruam nrog feem ntau ntawm kev ua lag luam yog tsim los ntawm cov khoom hu ua A thiab B, nrog rau cov khoom siv A yog polyethylene grafted nrog silane thiab cov khoom siv B yog cov khoom siv catalyst master batch. Lub hauv paus insulating tom qab ntawd raug cross-linked hauv dej sov lossis pa.

Muaj lwm hom ob kauj ruam silane cross-linked polyethylene insulator, qhov twg cov khoom siv A yog tsim tawm hauv txoj kev sib txawv, los ntawm kev qhia vinyl silane ncaj qha rau hauv polyethylene thaum lub sijhawm synthesis kom tau txais polyethylene nrog silane branched saw.

Txoj kev ib kauj ruam kuj muaj ob hom, cov txheej txheem ib kauj ruam ib txwm yog ntau yam khoom siv raw raws li cov mis hauv qhov sib piv ntawm cov txheej txheem ntsuas qhov tseeb tshwj xeeb, rau hauv cov extruder tshwj xeeb tsim hauv ib kauj ruam kom ua tiav cov grafting thiab extrusion ntawm cov tub ntxhais rwb thaiv tsev cable, hauv cov txheej txheem no, tsis muaj granulation, tsis tas yuav koom nrog cov khoom siv cable cog, los ntawm lub Hoobkas cable kom ua tiav ib leeg. Cov khoom siv cable ib kauj ruam silane cross-linked no thiab cov txheej txheem formulation feem ntau yog imported los ntawm txawv teb chaws thiab kim heev.

Lwm hom khoom siv rwb thaiv tsev silane cross-linked polyethylene ib kauj ruam yog tsim los ntawm cov chaw tsim khoom siv cable, yog txhua yam khoom siv raw raws li cov mis hauv qhov sib piv ntawm txoj kev tshwj xeeb ntawm kev sib tov ua ke, ntim thiab muag, tsis muaj cov khoom siv A thiab cov khoom siv B, cov nroj tsuag cable tuaj yeem ncaj qha rau hauv extruder kom ua tiav ib kauj ruam tib lub sijhawm grafting thiab extrusion ntawm cable rwb thaiv tsev core. Qhov tshwj xeeb ntawm txoj kev no yog tias tsis tas yuav siv cov extruders tshwj xeeb kim, vim tias cov txheej txheem silane grafting tuaj yeem ua tiav hauv PVC extruder ib txwm muaj, thiab txoj kev ob kauj ruam tshem tawm qhov xav tau sib tov A thiab B cov khoom siv ua ntej extrusion.

3. Cov qauv sib xyaw ua ke

Cov qauv ntawm silane cross-linked polyethylene cable khoom feem ntau yog tsim los ntawm cov khoom siv raw, cov tshuaj pib, silane, antioxidant, polymerization inhibitor, catalyst, thiab lwm yam.

(1) Cov tshuaj pleev xim feem ntau yog cov tshuaj polyethylene tsawg (LDPE) nrog cov ntsuas yaj (MI) ntawm 2, tab sis tsis ntev los no, nrog rau kev txhim kho cov thev naus laus zis hluavtaws thiab cov nqi siab, cov tshuaj polyethylene tsawg linear (LLDPE) kuj tau siv lossis siv ib feem ua cov tshuaj pleev xim rau cov khoom siv no. Cov tshuaj pleev xim sib txawv feem ntau muaj kev cuam tshuam loj rau kev sib txuas thiab kev sib txuas vim muaj qhov sib txawv hauv lawv cov qauv macromolecular sab hauv, yog li cov qauv yuav raug hloov kho los ntawm kev siv cov tshuaj pleev xim sib txawv lossis tib hom tshuaj pleev xim los ntawm cov chaw tsim khoom sib txawv.

(2) Tus neeg pib siv feem ntau yog diisopropyl peroxide (DCP), qhov tseem ceeb yog kom nkag siab txog qhov ntau ntawm qhov teeb meem, tsawg dhau los ua rau silane grafting tsis txaus; ntau dhau los ua rau polyethylene cross-linking, uas txo nws cov fluidity, qhov chaw ntawm extruded insulation core ntxhib, nyuaj rau nyem qhov system. Vim tias qhov ntau ntawm tus pib ntxiv yog me me thiab rhiab heev, nws yog ib qho tseem ceeb kom disperse nws sib npaug, yog li nws feem ntau ntxiv ua ke nrog silane.

(3) Silane feem ntau siv vinyl unsaturated silane, suav nrog vinyl trimethoxysilane (A2171) thiab vinyl triethoxysilane (A2151), vim yog qhov ceev hydrolysis ntawm A2171, yog li xaiv A2171 ntau tus neeg. Ib yam li ntawd, muaj teeb meem ntawm kev ntxiv silane, cov chaw tsim khoom siv cable tam sim no tab tom sim ua kom tiav nws qhov txwv qis dua kom txo cov nqi, vim tias silane raug xa tawm, tus nqi kim dua.

(4) Anti-oxidant yog los xyuas kom meej tias kev ua polyethylene thiab cable tiv thaiv kev laus thiab ntxiv, anti-oxidant hauv silane grafting txheej txheem muaj lub luag haujlwm ntawm kev tiv thaiv cov tshuaj tiv thaiv grafting, yog li cov txheej txheem grafting, ntxiv cov anti-oxidant kom ceev faj, qhov ntau ntxiv kom xav txog qhov ntau ntawm DCP kom phim qhov kev xaiv. Hauv ob kauj ruam cross-linking txheej txheem, feem ntau ntawm cov antioxidant tuaj yeem ntxiv rau hauv catalyst master batch, uas tuaj yeem txo qhov cuam tshuam rau cov txheej txheem grafting. Hauv ib kauj ruam cross-linking txheej txheem, cov antioxidant muaj nyob rau hauv tag nrho cov txheej txheem grafting, yog li kev xaiv ntawm hom thiab ntau npaum li cas tseem ceeb dua. Cov antioxidants feem ntau siv yog 1010, 168, 330, thiab lwm yam.

(5) Polymerization inhibitor ntxiv rau hauv kev txwv tsis pub qee qhov kev sib txuas thiab kev sib txuas ntawm cov tshuaj tiv thaiv sab tshwm sim, hauv cov txheej txheem grafting ntxiv tus neeg sawv cev tiv thaiv kev sib txuas, tuaj yeem txo qhov tshwm sim ntawm C2C cross-linking, yog li txhim kho cov txheej txheem ua haujlwm, ntxiv rau, qhov ntxiv ntawm graft hauv tib qho xwm txheej yuav ua ntej los ntawm hydrolysis ntawm silane ntawm polymerization inhibitor tuaj yeem txo qhov hydrolysis ntawm grafted polyethylene, los txhim kho kev ruaj khov mus sij hawm ntev ntawm cov khoom siv graft.

(6) Cov tshuaj catalysts feem ntau yog cov organotin derivatives (tshwj tsis yog natural crosslinking), feem ntau yog dibutyltin dilaurate (DBDTL), uas feem ntau ntxiv rau hauv daim ntawv ntawm masterbatch. Hauv ob kauj ruam, cov graft (A khoom) thiab cov catalyst master batch (B khoom) raug ntim sib cais thiab cov khoom A thiab B raug sib xyaw ua ke ua ntej ntxiv rau lub extruder kom tiv thaiv kev sib txuas ua ntej ntawm cov khoom A. Hauv cov ntaub ntawv ntawm ib kauj ruam silane cross-linked polyethylene insulations, polyethylene hauv pob tseem tsis tau grafted, yog li tsis muaj teeb meem ua ntej-cross-linking thiab yog li ntawd cov catalyst tsis tas yuav tsum tau ntim sib cais.

Tsis tas li ntawd xwb, muaj cov compounded silanes muaj nyob rau hauv kev ua lag luam, uas yog kev sib xyaw ua ke ntawm silane, initiator, antioxidant, qee cov roj nplua nyeem thiab cov neeg sawv cev tiv thaiv tooj liab, thiab feem ntau yog siv rau hauv ib kauj ruam silane cross-linking txoj kev hauv cov nroj tsuag cable.

Yog li ntawd, kev tsim cov silane cross-linked polyethylene rwb thaiv tsev, cov khoom sib xyaw uas tsis suav tias yog qhov nyuaj heev thiab muaj nyob rau hauv cov ntaub ntawv cuam tshuam, tab sis cov qauv tsim khoom tsim nyog, raug rau qee qhov kev hloov kho kom tiav, uas yuav tsum muaj kev nkag siab tag nrho txog lub luag haujlwm ntawm cov khoom hauv cov qauv thiab txoj cai ntawm lawv qhov cuam tshuam rau kev ua tau zoo thiab lawv cov kev cuam tshuam sib koom ua ke.

Hauv ntau yam khoom siv cable, silane cross-linked cable khoom (ob kauj ruam lossis ib kauj ruam) yog suav tias yog tib yam tshuaj lom neeg tshwm sim hauv extrusion, lwm yam xws li polyvinyl chloride (PVC) cable khoom thiab polyethylene (PE) cable khoom, extrusion granulation txheej txheem yog ib qho kev sib xyaw ua ke, txawm tias cov tshuaj lom neeg cross-linking thiab irradiation cross-linking cable khoom, txawm tias nyob rau hauv extrusion granulation txheej txheem, lossis extrusion system Cable, tsis muaj cov txheej txheem tshuaj lom neeg tshwm sim, yog li, piv rau kev tsim cov silane cross-linked cable khoom thiab cable rwb thaiv tsev extrusion, kev tswj hwm txheej txheem tseem ceeb dua.

4. Cov txheej txheem tsim cov khoom siv rwb thaiv tsev polyethylene ob kauj ruam

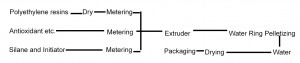

Cov txheej txheem tsim khoom ntawm ob-kauj ruam silane cross-linked polyethylene rwb thaiv tsev A khoom siv tuaj yeem sawv cev luv luv los ntawm Daim Duab 1.

Daim Duab 1 Cov txheej txheem tsim khoom ntawm ob-kauj ruam silane cross-linked polyethylene insulating khoom A

Qee cov ntsiab lus tseem ceeb hauv cov txheej txheem tsim khoom ntawm ob kauj ruam silane cross-linked polyethylene rwb thaiv tsev:

(1) Kev ziab. Vim tias cov polyethylene resin muaj me ntsis dej, thaum extruded ntawm qhov kub siab, cov dej reacts sai nrog cov pab pawg silyl los tsim kev sib txuas, uas txo qhov fluidity ntawm yaj thiab tsim pre-cross-linking. Cov khoom tiav lawm kuj muaj dej tom qab dej txias, uas kuj tuaj yeem ua rau pre-crosslinking yog tias tsis tshem tawm, thiab yuav tsum tau ziab. Yuav kom ntseeg tau tias qhov zoo ntawm kev ziab, chav ziab tob siv.

(2) Kev ntsuas. Vim tias qhov tseeb ntawm cov khoom siv yog qhov tseem ceeb, feem ntau siv cov nplai ntsuas qhov hnyav uas xa tawm los ntawm txawv teb chaws. Cov polyethylene resin thiab antioxidant raug ntsuas thiab pub los ntawm qhov chaw pub ntawm lub extruder, thaum cov silane thiab initiator raug txhaj los ntawm lub twj tso kua mis hauv lub thoob thib ob lossis thib peb ntawm lub extruder.

(3) Kev rho tawm cov khoom siv. Cov txheej txheem rho tawm cov silane tiav hauv lub tshuab extruder. Cov txheej txheem teeb tsa ntawm lub tshuab extruder, suav nrog qhov kub, kev sib xyaw ua ke ntawm cov ntsia hlau, qhov ceev ntawm cov ntsia hlau thiab qhov nrawm pub, yuav tsum ua raws li lub hauv paus ntsiab lus tias cov khoom siv hauv thawj ntu ntawm lub tshuab extruder tuaj yeem yaj tag nrho thiab sib xyaw ua ke, thaum tsis xav tau kev lwj ua ntej ntawm cov peroxide, thiab tias cov khoom siv sib xws hauv ntu thib ob ntawm lub tshuab extruder yuav tsum tau lwj tag nrho thiab cov txheej txheem rho tawm ua tiav. Cov kub ntawm ntu extruder (LDPE) ib txwm muaj nyob rau hauv Rooj 1.

Rooj 1 Qhov Kub ntawm ob-kauj ruam extruder zones

| Thaj chaw ua haujlwm | Cheeb Tsam 1 | Cheeb Tsam 2 | Cheeb Tsam 3 ① | Cheeb Tsam 4 | Cheeb Tsam 5 |

| Kub P ° C | 140 | 145 | 120 | 160 | 170 |

| Thaj chaw ua haujlwm | Cheeb Tsam 6 | Cheeb Tsam 7 | Cheeb Tsam 8 | Cheeb Tsam 9 | Qhov ncauj tuag |

| Kub thiab txias °C | 180 | 190 | 195 | 205 | 195 |

①is qhov twg cov silane ntxiv.

Qhov ceev ntawm lub extruder ntsia hlau txiav txim siab lub sijhawm nyob thiab cov nyhuv sib tov ntawm cov khoom siv hauv extruder, yog tias lub sijhawm nyob luv luv, qhov peroxide decomposition tsis tiav; yog tias lub sijhawm nyob ntev dhau, qhov viscosity ntawm cov khoom extruded nce ntxiv. Feem ntau, lub sijhawm nyob nruab nrab ntawm cov granule hauv extruder yuav tsum tau tswj hwm hauv lub sijhawm decomposition pib ntawm 5-10 zaug. Kev pub noj ceev tsis yog tsuas yog muaj qee qhov cuam tshuam rau lub sijhawm nyob ntawm cov khoom siv, tab sis kuj rau kev sib tov thiab shearing ntawm cov khoom siv, xaiv qhov ceev pub noj kom tsim nyog kuj tseem ceeb heev.

(4) Ntim Khoom. Cov khoom siv rwb thaiv tsev silane cross-linked ob kauj ruam yuav tsum tau ntim rau hauv cov hnab yas txhuas hauv cov huab cua ncaj qha kom tshem tawm cov dej noo.

5. Ib kauj ruam silane cross-linked polyethylene insulating khoom ntau lawm txheej txheem

Ib kauj ruam silane cross-linked polyethylene rwb thaiv tsev cov khoom siv vim nws cov txheej txheem grafting yog nyob rau hauv lub Hoobkas cable extrusion ntawm cable rwb thaiv tsev core, yog li cable rwb thaiv tsev extrusion kub yog siab dua li ob kauj ruam. Txawm hais tias ib kauj ruam silane cross-linked polyethylene rwb thaiv tsev mis tau raug txiav txim siab tag nrho hauv kev sib kis sai ntawm initiator thiab silane thiab cov khoom shear, tab sis cov txheej txheem grafting yuav tsum tau lees paub los ntawm qhov kub, uas yog ib kauj ruam silane cross-linked polyethylene rwb thaiv tsev ntau zaus hais txog qhov tseem ceeb ntawm kev xaiv qhov kub extrusion kom raug, qhov kub extrusion pom zoo dav dav tau qhia hauv Rooj 2.

Rooj 2 Ib kauj ruam extruder kub ntawm txhua cheeb tsam (chav tsev: ℃)

| Thaj Chaw | Cheeb Tsam 1 | Cheeb Tsam 2 | Cheeb Tsam 3 | Cheeb Tsam 4 | Flange | Lub taub hau |

| Kub | 160 | 190 | 200 ~ 210 | 220 ~ 230 | 230 | 230 |

Qhov no yog ib qho ntawm qhov tsis muaj zog ntawm cov txheej txheem polyethylene ib kauj ruam silane cross-linked, uas feem ntau tsis tas yuav tsum tau thaum extruding cables hauv ob kauj ruam.

6. Cov khoom siv tsim khoom

Cov khoom siv tsim khoom yog qhov tseem ceeb ntawm kev tswj cov txheej txheem. Kev tsim cov kab txuas silane xav tau qib siab ntawm kev tswj cov txheej txheem raug, yog li kev xaiv cov khoom siv tsim khoom tseem ceeb heev.

Kev tsim cov khoom siv rwb thaiv tsev ob kauj ruam silane cross-linked polyethylene A cov khoom siv tsim khoom, tam sim no ntau dua hauv tsev isotropic parallel twin-screw extruder nrog cov khoom siv tsis hnyav, cov khoom siv no tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev tswj hwm qhov tseeb, kev xaiv qhov ntev thiab txoj kab uas hla ntawm twin-screw extruder kom ntseeg tau tias cov khoom siv nyob rau lub sijhawm, kev xaiv cov khoom siv tsis hnyav los ntawm txawv teb chaws kom ntseeg tau qhov tseeb ntawm cov khoom xyaw. Tau kawg muaj ntau cov ntsiab lus ntawm cov khoom siv uas yuav tsum tau muab kev saib xyuas tag nrho.

Raws li tau hais ua ntej lawm, cov khoom siv tsim cov cable silane cross-linked ib kauj ruam hauv cov nroj tsuag cable yog cov khoom xa tuaj txawv teb chaws, kim heev, cov chaw tsim khoom siv hauv tsev tsis muaj cov khoom siv zoo sib xws, qhov laj thawj yog tsis muaj kev koom tes ntawm cov chaw tsim khoom siv thiab cov kws tshawb fawb txog cov mis thiab cov txheej txheem.

7. Silane ntuj cross-linked polyethylene rwb thaiv tsev khoom

Cov khoom siv rwb thaiv tsev polyethylene uas yog silane ntuj tsim uas tau tsim nyob rau xyoo tas los no tuaj yeem sib txuas ua ke hauv qab ntuj hauv ob peb hnub xwb, tsis tas siv dej kub los yog siv dej kub. Piv nrog rau txoj kev sib txuas silane ib txwm muaj, cov khoom no tuaj yeem txo cov txheej txheem tsim khoom rau cov tuam txhab tsim cable, txo cov nqi tsim khoom ntxiv thiab ua kom cov khoom siv tau zoo dua. Cov khoom siv rwb thaiv tsev polyethylene uas yog silane ntuj tsim tau lees paub thiab siv ntau dua los ntawm cov tuam txhab tsim cable.

Nyob rau hauv xyoo tas los no, cov khoom siv polyethylene silane ntuj tsim tau loj hlob thiab tau tsim tawm ntau heev, nrog rau qee qhov zoo hauv tus nqi piv rau cov khoom siv txawv teb chaws.

7. 1 Cov tswv yim tsim rau silane naturally cross-linked polyethylene insulations

Cov khoom siv rwb thaiv tsev silane ntuj cross-linked polyethylene yog tsim tawm hauv ob kauj ruam, nrog rau tib cov qauv uas muaj cov resin hauv paus, tus pib, silane, antioxidant, polymerisation inhibitor thiab catalyst. Cov qauv ntawm silane ntuj cross-linked polyethylene insulators yog raws li kev nce tus nqi silane grafting ntawm cov khoom siv A thiab xaiv cov catalyst zoo dua li silane dej sov cross-linked polyethylene insulators. Kev siv cov khoom siv A nrog tus nqi silane grafting siab dua ua ke nrog cov catalyst zoo dua yuav ua rau cov khoom siv rwb thaiv tsev silane cross-linked polyethylene kom cross-link sai txawm tias nyob rau qhov kub qis thiab tsis txaus noo noo.

Cov khoom siv A-rau cov khoom siv silane uas tau xa tawm los ntawm cov khoom siv polyethylene uas tau sib txuas ua ke yog tsim los ntawm kev sib xyaw ua ke, qhov twg cov ntsiab lus silane tuaj yeem tswj tau ntawm qib siab, thaum kev tsim cov khoom siv A-nrog cov nqi grafting siab los ntawm kev siv silane grafting yog qhov nyuaj. Cov resin puag, initiator thiab silane siv hauv daim ntawv qhia yuav tsum tau hloov pauv thiab kho kom haum rau ntau yam thiab ntxiv.

Qhov kev xaiv ntawm qhov tiv thaiv thiab kev hloov kho ntawm nws cov koob tshuaj kuj tseem ceeb heev, vim tias kev nce ntxiv ntawm tus nqi grafting ntawm silane inevitably ua rau muaj ntau CC crosslinking sab tshuag. Txhawm rau txhim kho cov txheej txheem ua haujlwm thiab qhov chaw ntawm cov khoom siv A rau kev txuas cable tom qab, yuav tsum muaj cov tshuaj polymerization inhibitor kom zoo kom tiv thaiv CC crosslinking thiab ua ntej crosslinking.

Tsis tas li ntawd xwb, cov catalysts ua lub luag haujlwm tseem ceeb hauv kev nce tus nqi crosslinking thiab yuav tsum tau xaiv ua cov catalysts zoo uas muaj cov khoom tsis muaj hlau hloov pauv.

7. 2 Lub sijhawm sib txuas ntawm silane ntuj tsim crosslinked polyethylene insulations

Lub sijhawm uas yuav tsum tau ua kom tiav qhov kev sib txuas ntawm silane ntuj cross-linked polyethylene rwb thaiv tsev hauv nws lub xeev ntuj yog nyob ntawm qhov kub, av noo thiab tuab ntawm cov txheej rwb thaiv tsev. Qhov kub thiab av noo siab dua, qhov tuab ntawm cov txheej rwb thaiv tsev nyias dua, lub sijhawm sib txuas luv dua, thiab qhov sib txawv ntev dua. Raws li qhov kub thiab av noo sib txawv ntawm thaj chaw mus rau thaj chaw thiab los ntawm lub caij mus rau lub caij, txawm tias nyob hauv tib qho chaw thiab tib lub sijhawm, qhov kub thiab av noo hnub no thiab tag kis yuav txawv. Yog li ntawd, thaum siv cov khoom siv, tus neeg siv yuav tsum txiav txim siab lub sijhawm sib txuas raws li qhov kub thiab av noo hauv zos thiab tam sim no, nrog rau qhov kev qhia tshwj xeeb ntawm cov xov hlau thiab qhov tuab ntawm cov txheej rwb thaiv tsev.

Lub sijhawm tshaj tawm: Lub Yim Hli-13-2022