Hauv kev tsim qauv ntawm cov qauv tshiabtiv taus hluav tawscov xov hlau,Cov polyethylene txuas nrog (XLPE) rwb thaiv tsevCov cables siv dav dav. Lawv ua tau zoo heev rau kev ua haujlwm hluav taws xob, cov khoom siv kho tshuab, thiab kev ruaj khov ib puag ncig. Cov yam ntxwv los ntawm qhov kub thiab txias ua haujlwm siab, muaj peev xwm kis tau ntau, tsis muaj kev txwv, thiab yooj yim rau kev teeb tsa thiab txij nkawm, lawv sawv cev rau kev coj ua ntawm cov cables tshiab.

1. Kev Tsim Tus Neeg Hlau Cable

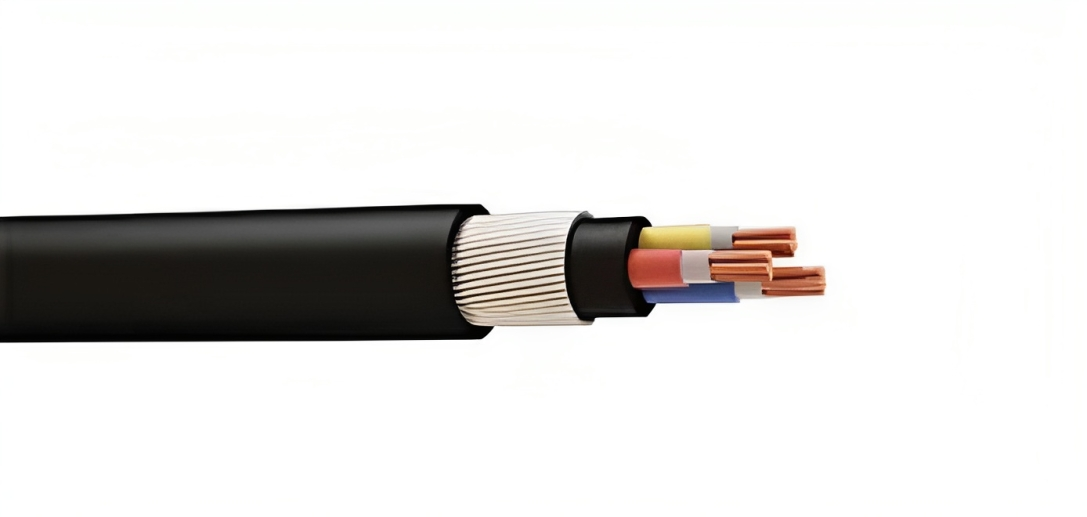

Cov Qauv thiab Cov Yam Ntxwv ntawm Tus Neeg Txuas: Cov qauv ntawm tus neeg txuas siv cov qauv thib ob uas zoo li kiv cua, siv cov qauv sib txuas (1 + 6 + 12 + 18 + 24). Hauv cov hlua khi ib txwm, txheej nruab nrab muaj ib txoj hlua, txheej thib ob muaj rau txoj hlua, thiab cov txheej sib txuas tom qab sib txawv los ntawm rau txoj hlua. Txheej sab nraud tshaj plaws yog sab laug, thaum lwm cov txheej sib txuas yog hlua khi rau hauv qhov kev taw qhia rov qab. Cov hlua yog puag ncig thiab muaj qhov sib npaug, ua kom muaj kev ruaj khov hauv cov qauv hlua khi no. Cov qauv sib txuas: Los ntawm kev sib txuas, qhov chaw ntawm tus neeg txuas ua du, zam kev sib sau ua ke ntawm cov teb hluav taws xob. Tib lub sijhawm, nws tiv thaiv cov khoom siv semi-conductive los ntawm kev nkag mus rau hauv lub plawv hlau thaum lub sijhawm extrusion rwb thaiv tsev, tiv thaiv kev nkag mus rau hauv dej noo thiab ua kom muaj qee qib ntawm kev ywj pheej. Cov neeg txuas hlua muaj kev ywj pheej zoo, kev ntseeg siab, thiab lub zog siab.

2. Txheej rwb thaiv tsev cableTsim Qauv

Lub luag haujlwm ntawm cov txheej rwb thaiv tsev yog los xyuas kom meej tias cov cable ua haujlwm hluav taws xob thiab tiv thaiv cov dej ntws ntawm cov neeg coj los ntawm kev xau sab nraud. Ib qho qauv extrusion yog siv, nrogCov khoom siv XLPEXaiv rau kev rwb thaiv tsev. XLPE muaj kev ua tau zoo dua li polyethylene, muaj cov khoom rwb thaiv tsev zoo heev, uas muaj qhov tsis tshua muaj dielectric constants (ε) thiab dielectric loss tangent qis (tgδ). Nws yog cov khoom rwb thaiv tsev zoo tagnrho rau zaus siab. Nws cov coefficient tiv taus ntim thiab lub zog tawg tseem tsis hloov pauv txawm tias tom qab xya hnub ntawm kev immersion hauv dej. Yog li ntawd, nws yog siv dav hauv kev rwb thaiv tsev cable. Txawm li cas los xij, nws muaj qhov melting point qis. Thaum siv rau hauv cables, overcurrent lossis luv-circuit faults yuav ua rau kub nce, ua rau softening thiab deformation ntawm polyethylene, ua rau rwb thaiv tsev puas tsuaj. Txhawm rau khaws cov txiaj ntsig ntawm polyethylene, nws dhau los ntawm kev sib txuas, txhim kho nws qhov kev tiv thaiv kub thiab tiv thaiv kev ntxhov siab ib puag ncig, ua rau cov khoom siv polyethylene sib txuas ua cov khoom rwb thaiv tsev zoo tagnrho.

3. Kev Tsim Kab Hlau thiab Kev Qhwv

Lub hom phiaj ntawm kev khi thiab qhwv cov xov hlau yog los tiv thaiv cov rwb thaiv tsev, xyuas kom lub hauv paus cable ruaj khov, thiab tiv thaiv cov rwb thaiv tsev thiab cov khoom sau xoob, xyuas kom meej tias lub hauv paus puag ncig. Lubsiv txoj siv sia tiv thaiv hluav tawsmuab qee yam khoom uas tiv taus hluav taws.

Cov ntaub ntawv rau Cable Stranding thiab Wrapping: Cov ntaub ntawv qhwv yog cov khoom siv hluav taws kub-retardantcov ntaub tsis yog wovensiv, nrog lub zog tensile thiab qhov ntsuas hluav taws kub ntawm tsis tsawg dua 55% cov ntsuas oxygen. Cov khoom siv filler siv cov hlua ntawv inorganic uas tsis muaj hluav taws kub (cov hlua mineral), uas mos, nrog cov ntsuas oxygen ntawm tsis tsawg dua 30%. Cov kev cai rau kev khi thiab qhwv cable suav nrog kev xaiv qhov dav ntawm cov hlua qhwv raws li lub hauv paus txoj kab uas hla thiab lub kaum sab xis ntawm cov hlua, nrog rau qhov sib tshooj lossis qhov sib nrug ntawm kev qhwv. Kev taw qhia qhwv yog sab laug. Cov siv tawv uas muaj hluav taws kub siab yog qhov yuav tsum tau rau cov siv tawv uas tsis muaj hluav taws kub. Qhov tiv taus cua sov ntawm cov khoom siv filler yuav tsum phim qhov kub ua haujlwm ntawm cable, thiab nws cov khoom sib xyaw yuav tsum tsis txhob cuam tshuam tsis zoo nrogcov khoom siv rwb thaiv tsev.Nws yuav tsum tau tshem tawm yam tsis muaj kev puas tsuaj rau lub hauv paus rwb thaiv tsev.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-12-2023